010 Sand casting

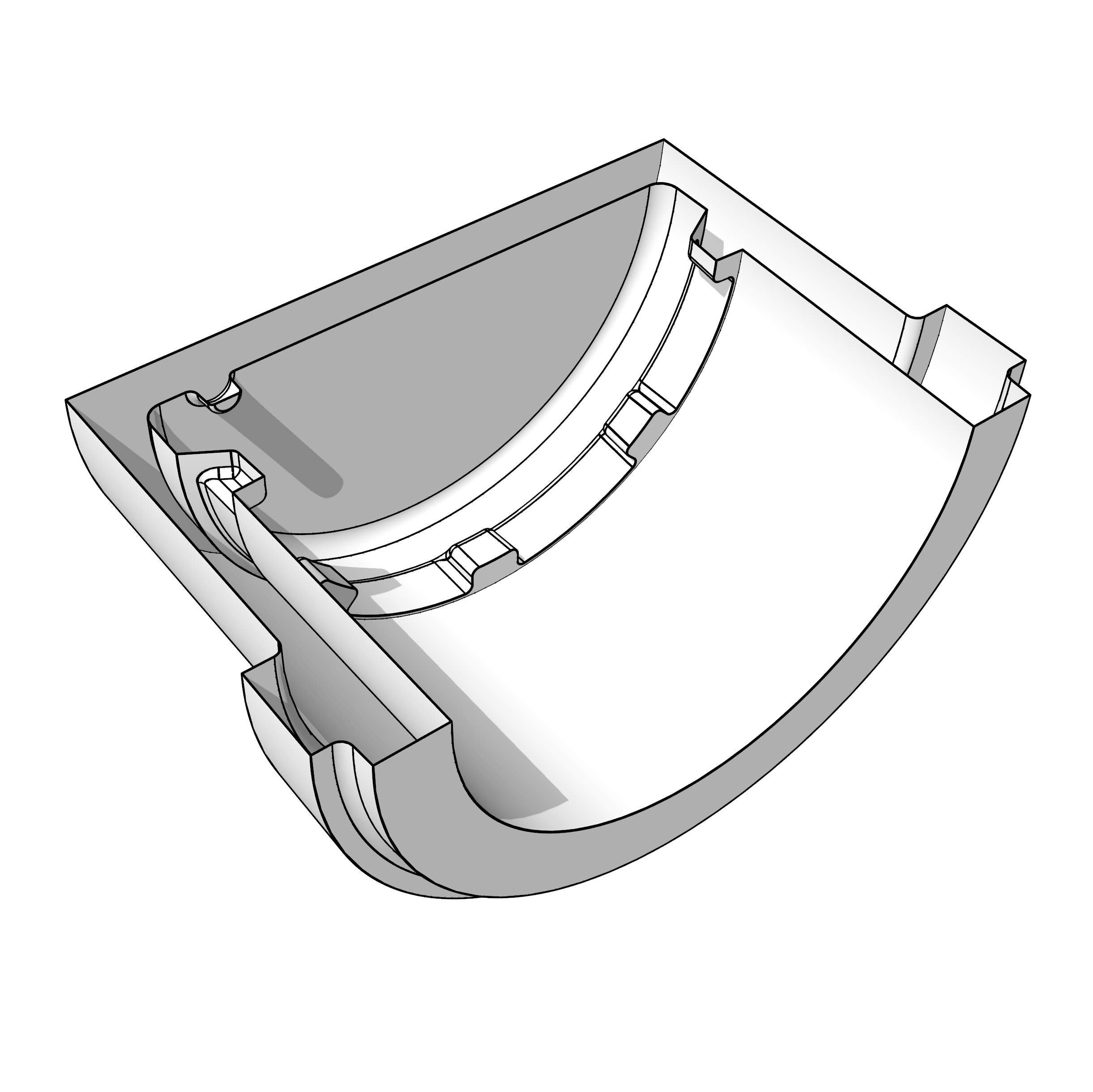

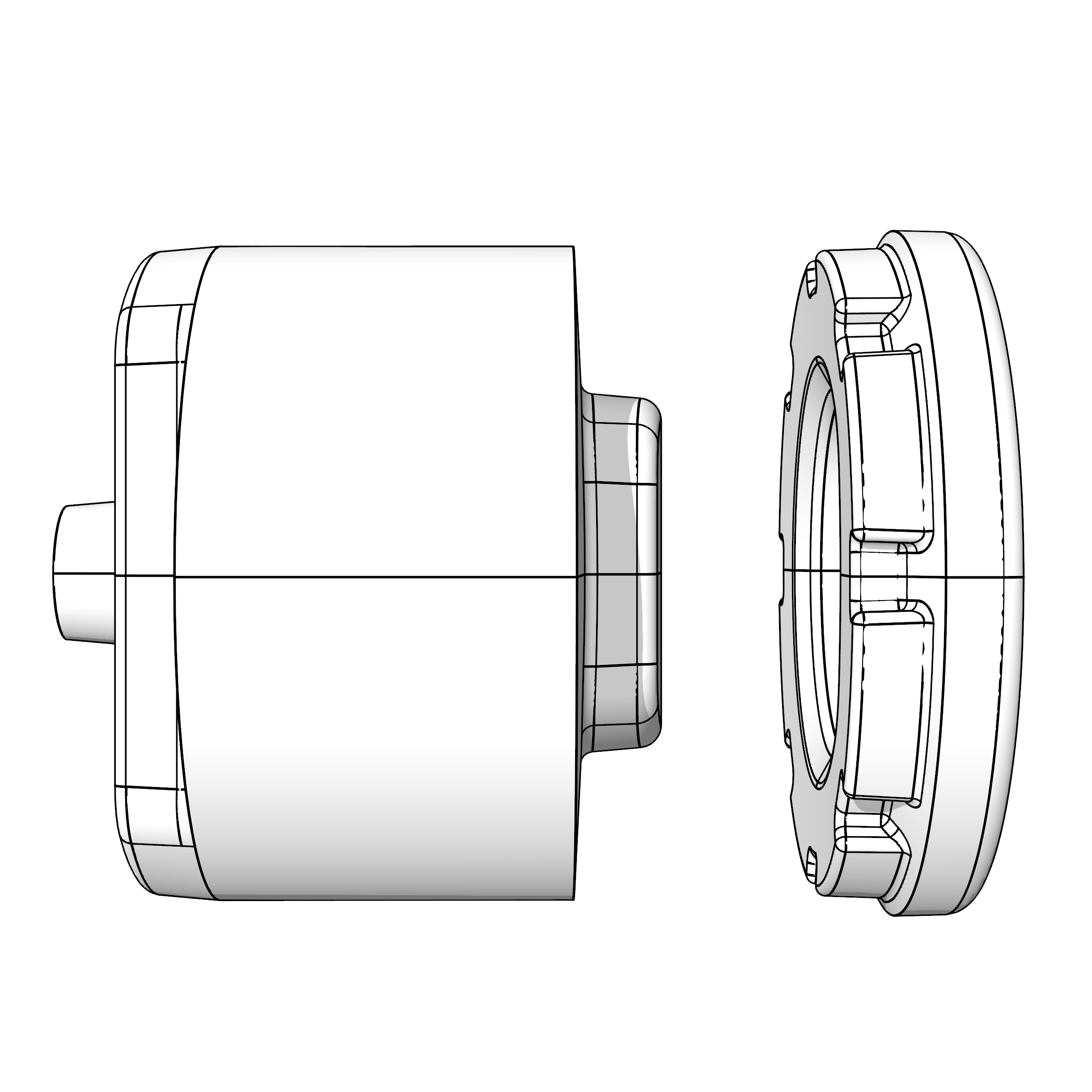

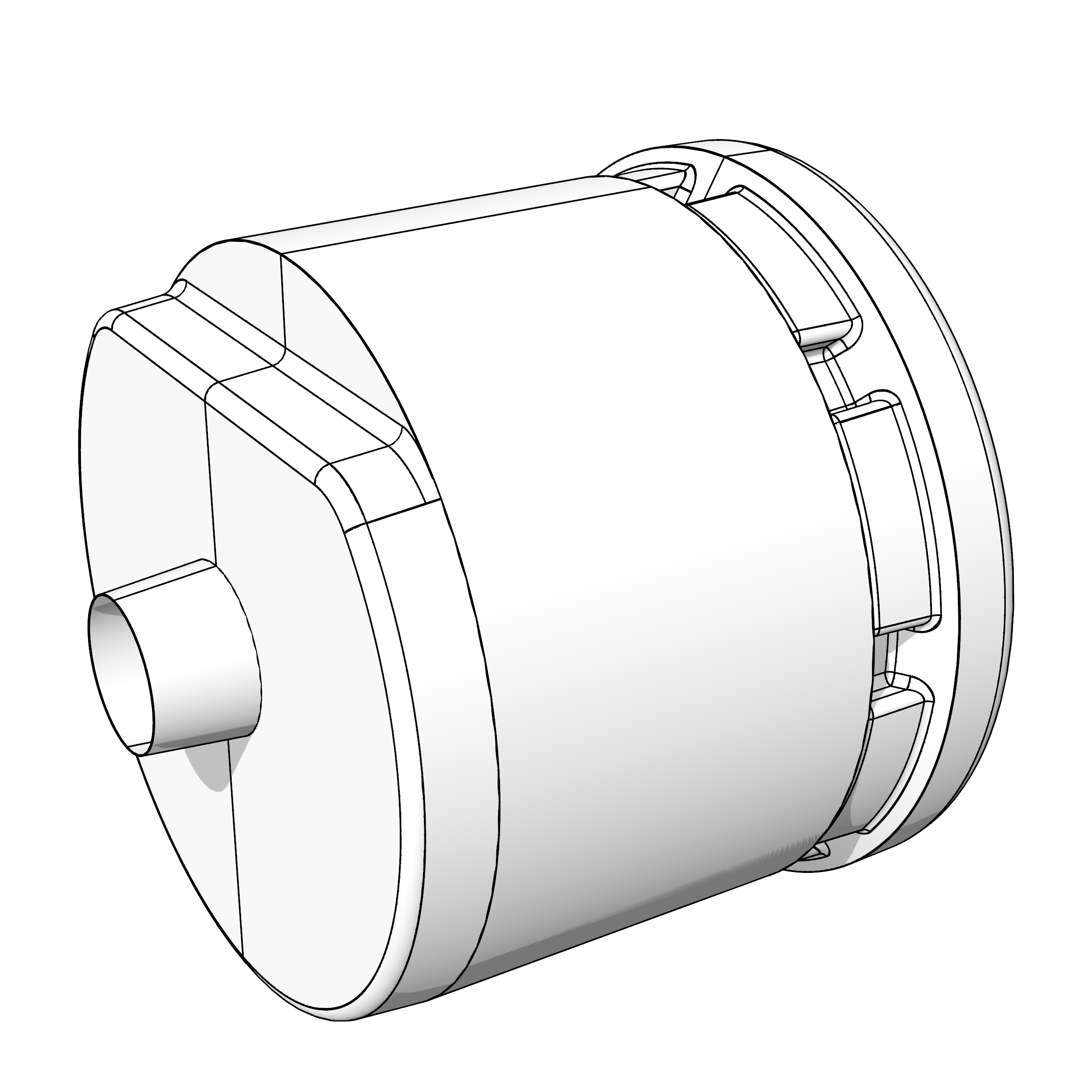

This foundry project starts with an existing 3D model, which serves as the basis for the necessary adjustments. In order to meet the specific requirements of the casting process, targeted changes are made that take into account mold chamfers, fillets, machining allowances and shrinkage.

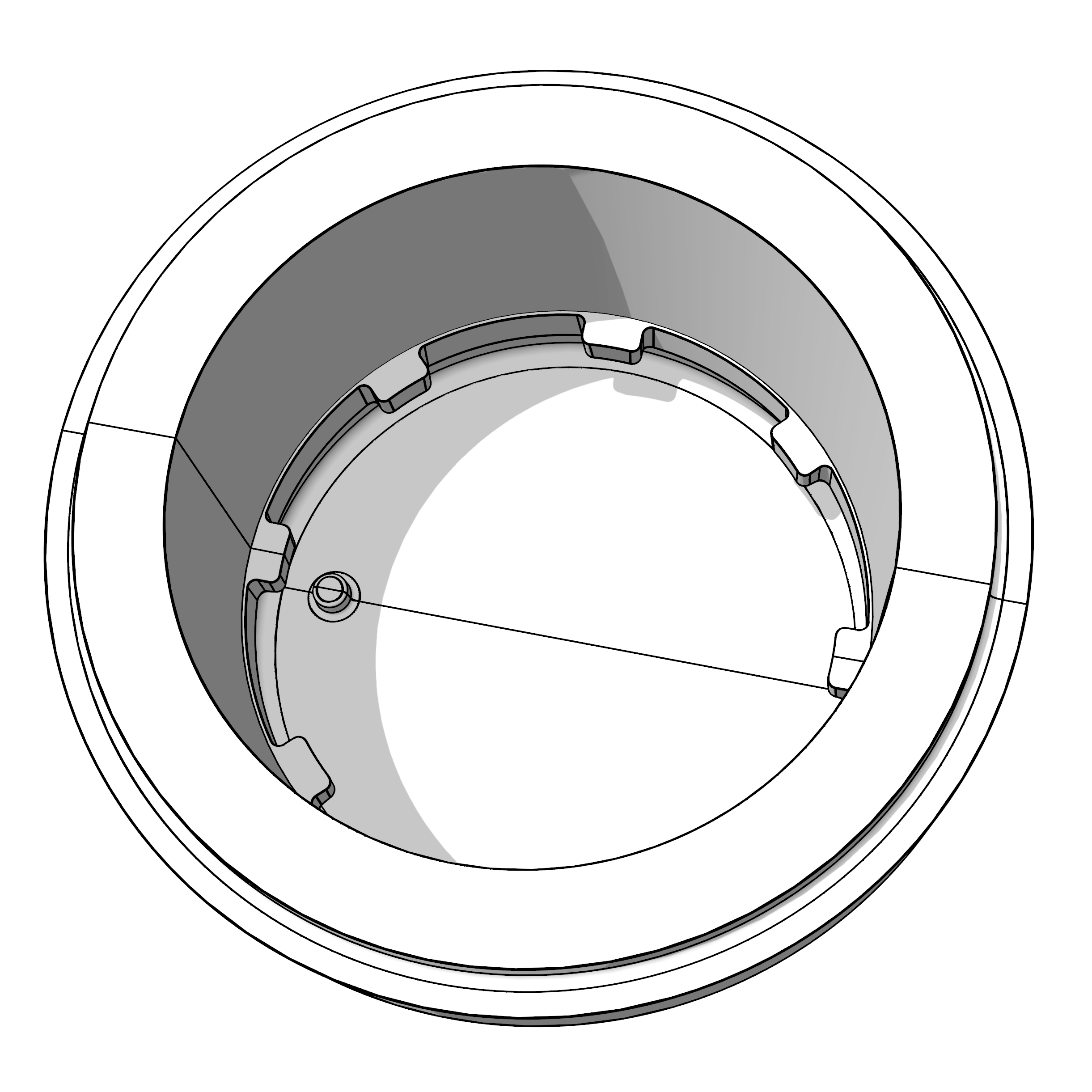

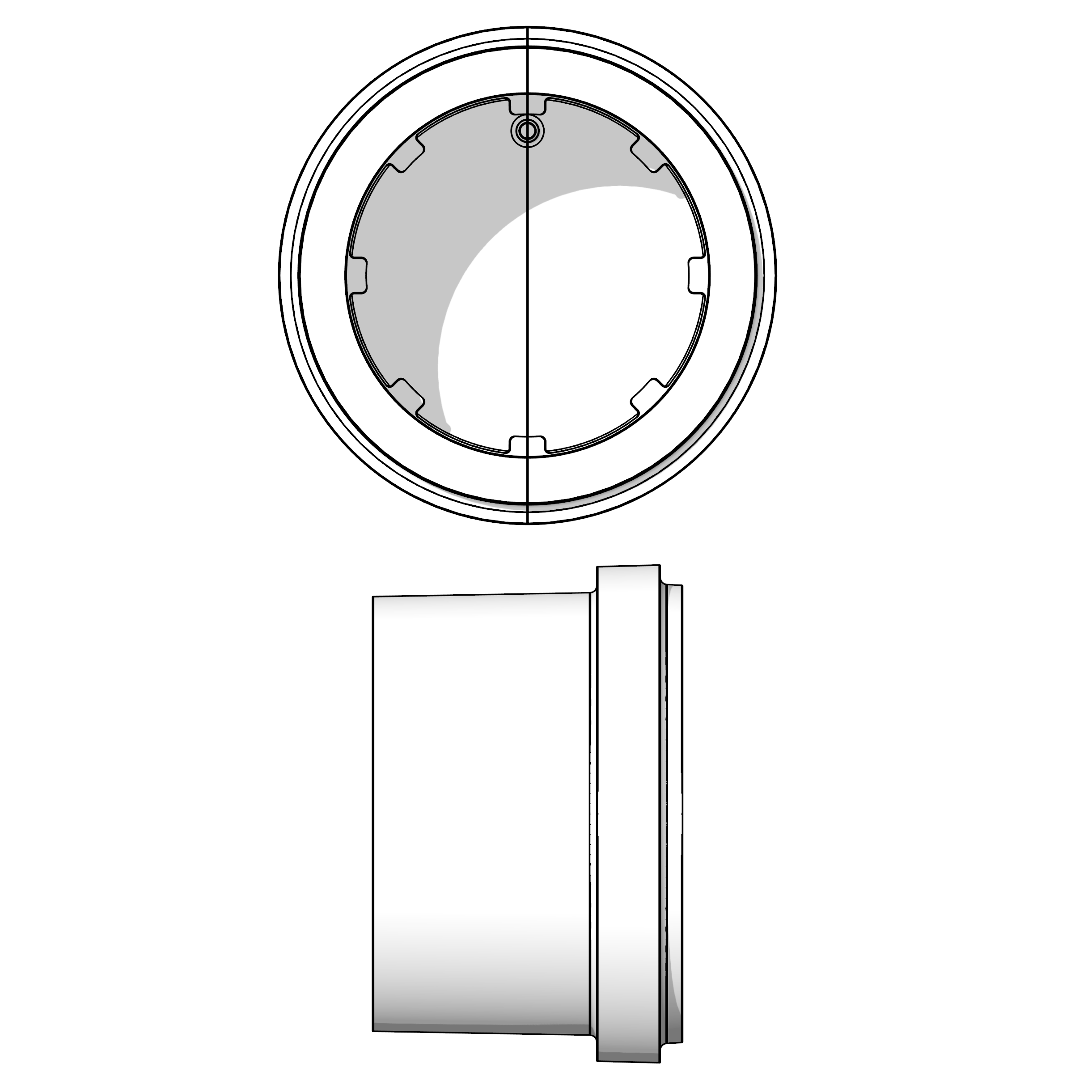

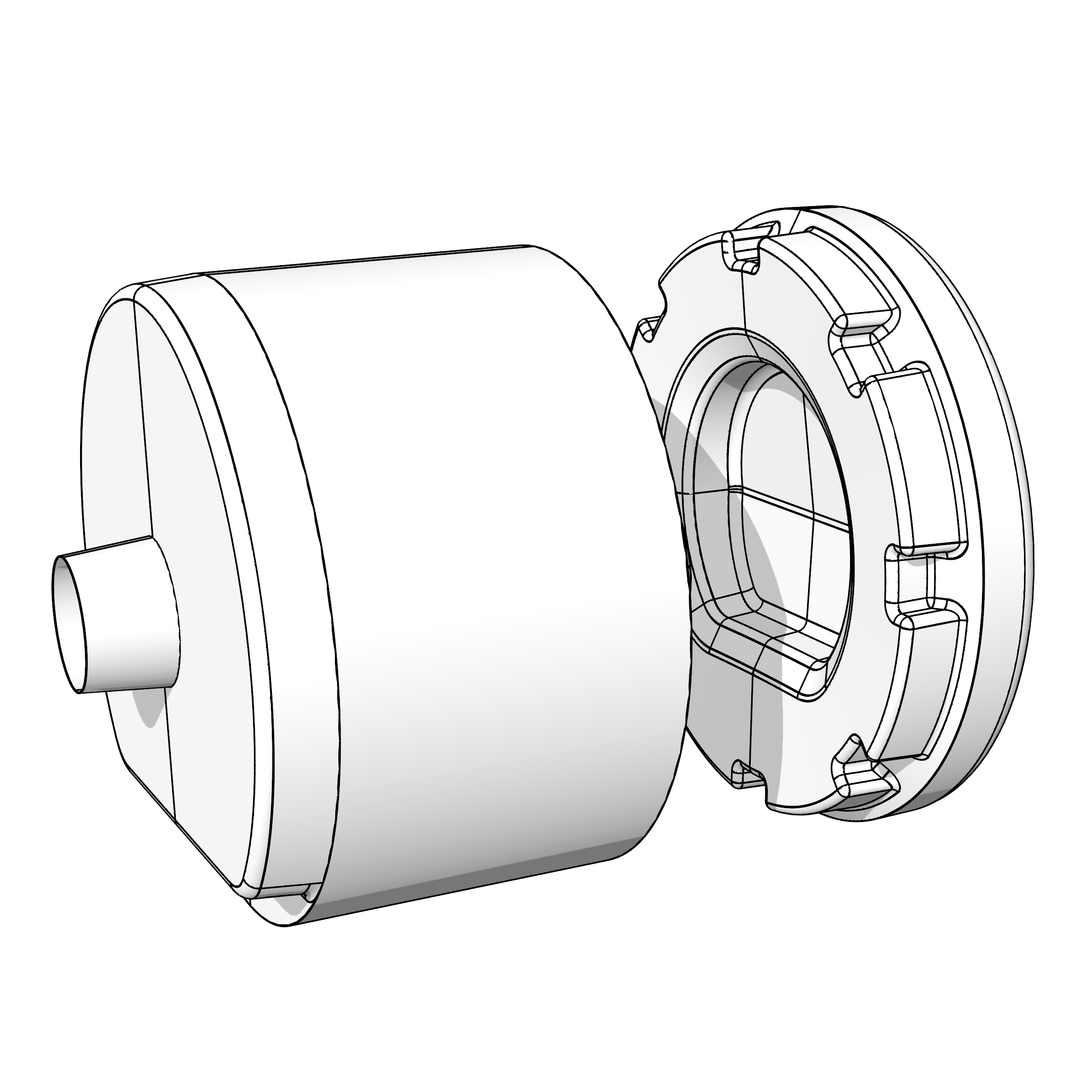

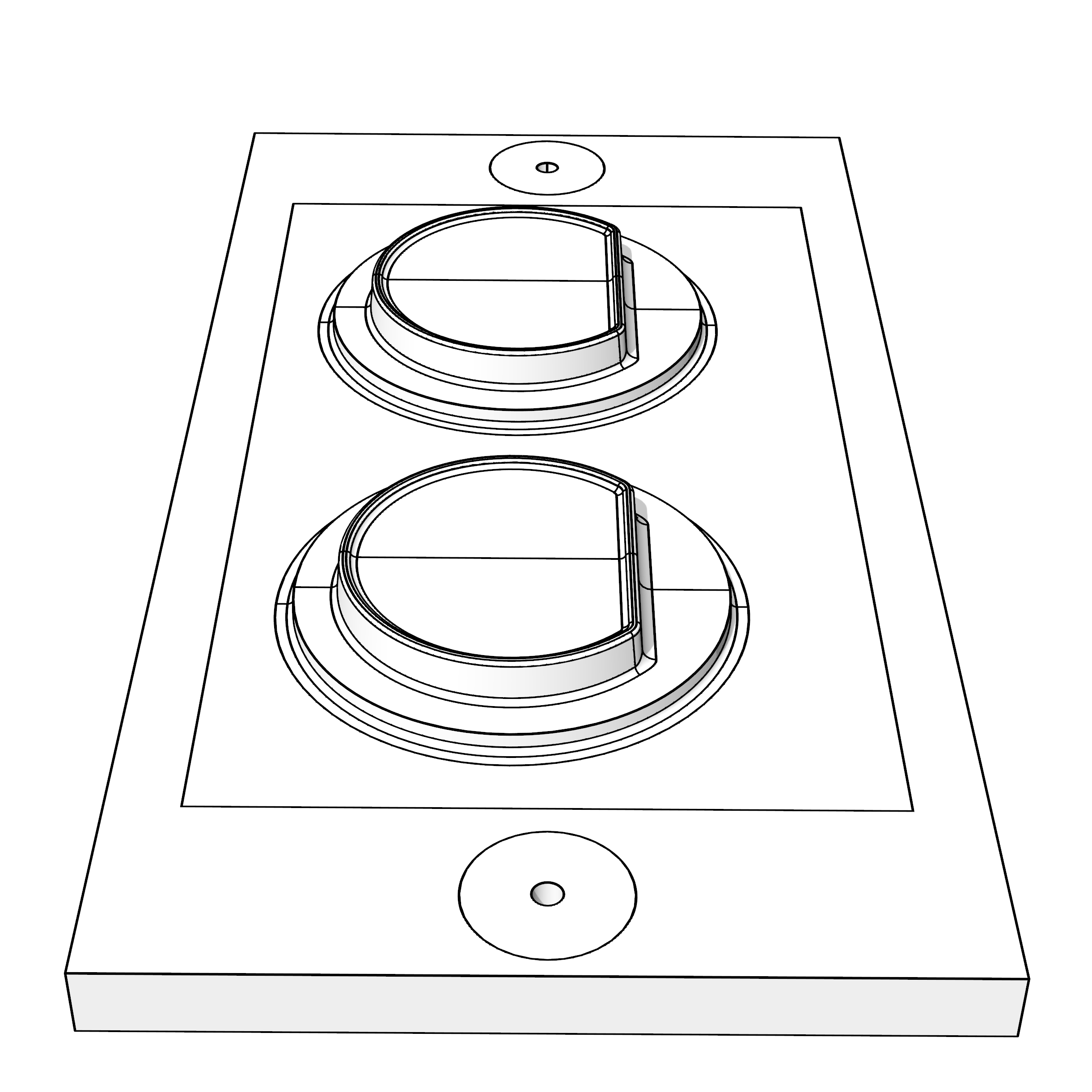

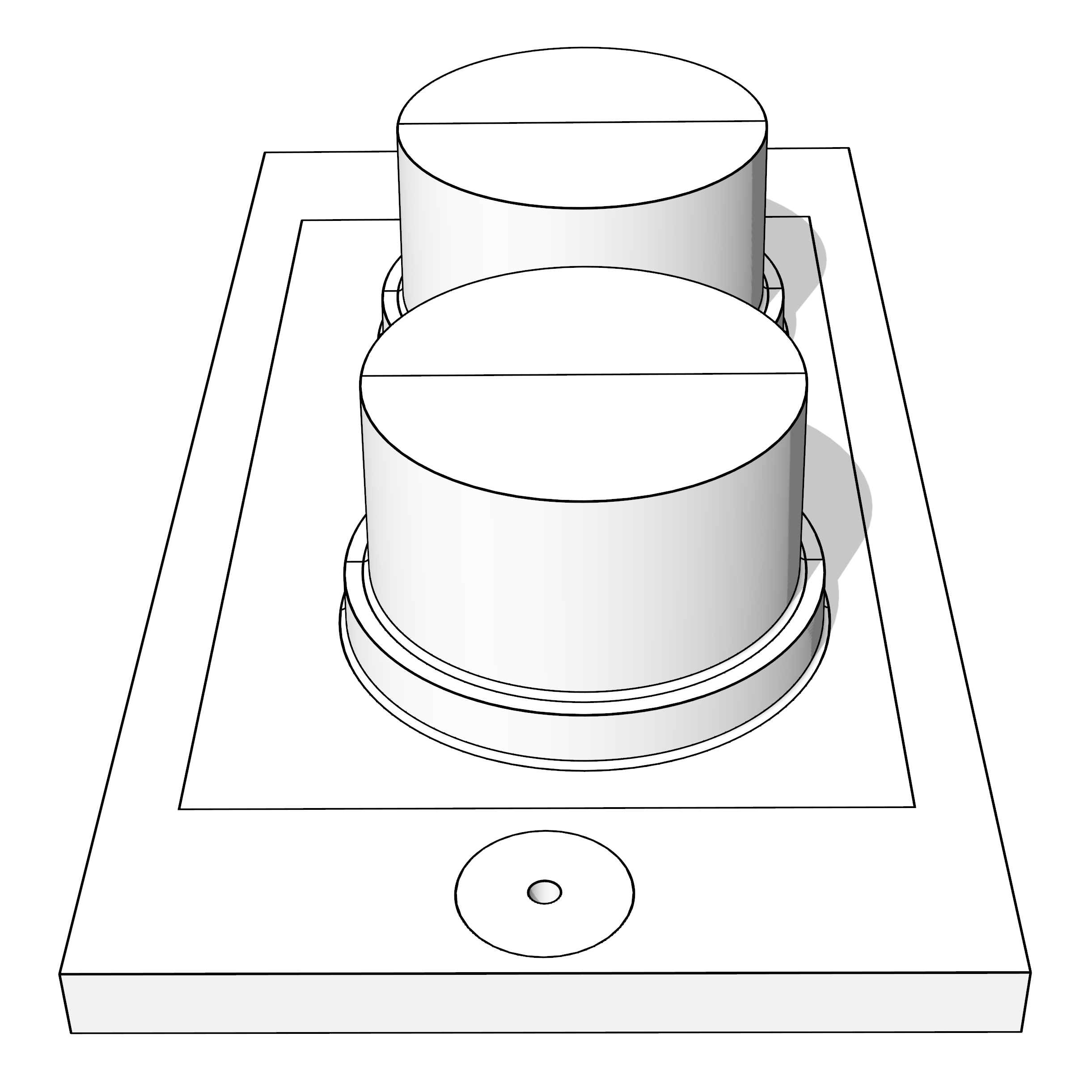

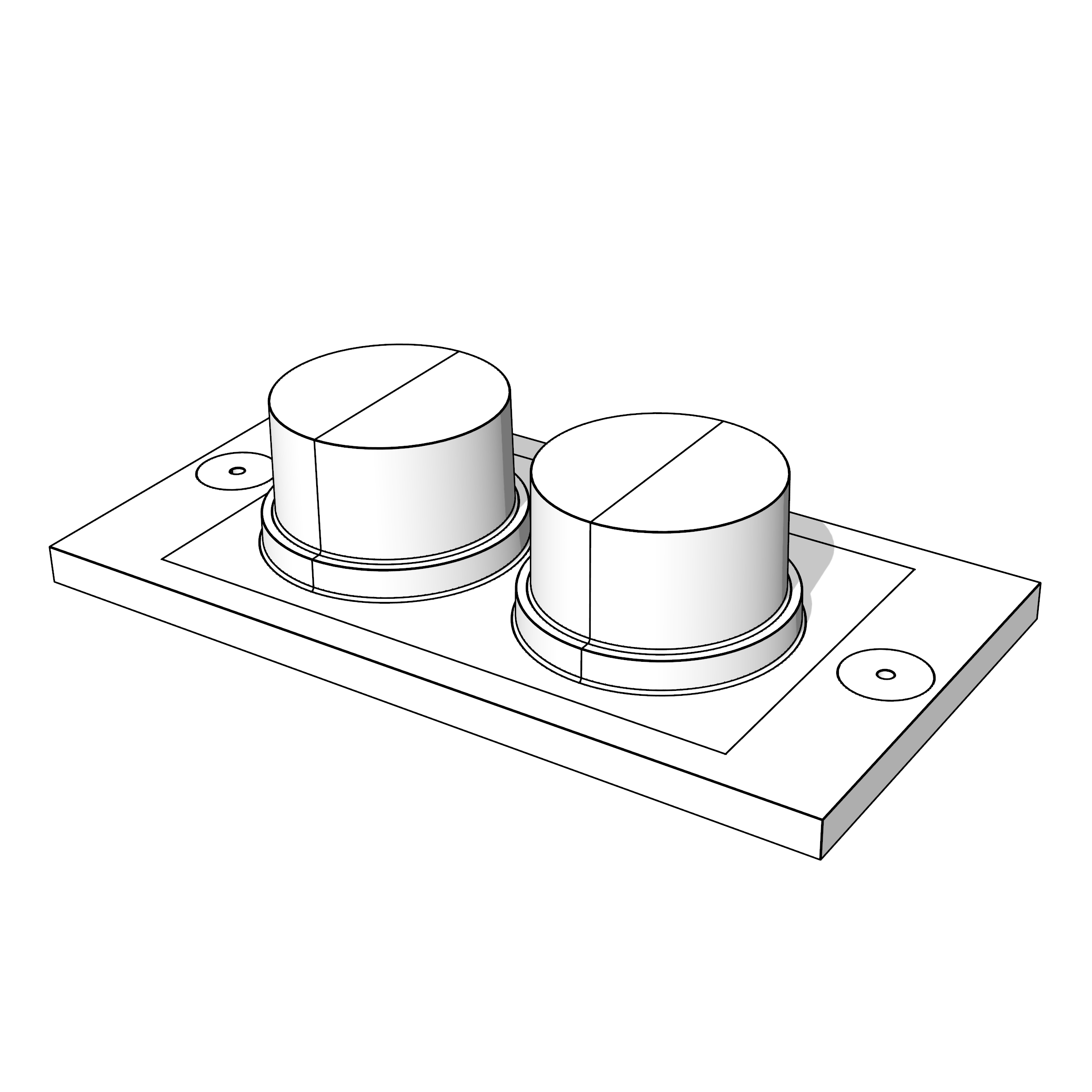

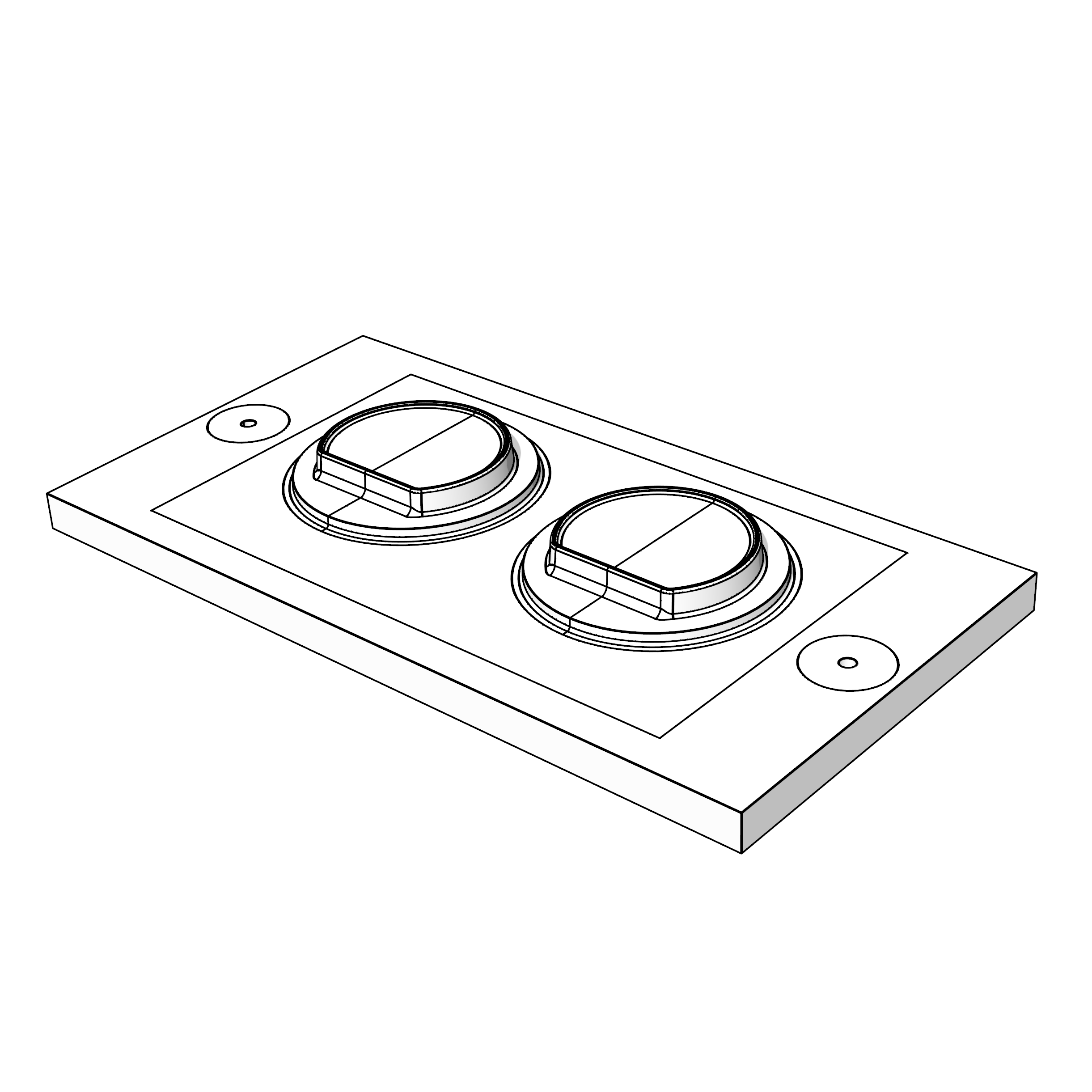

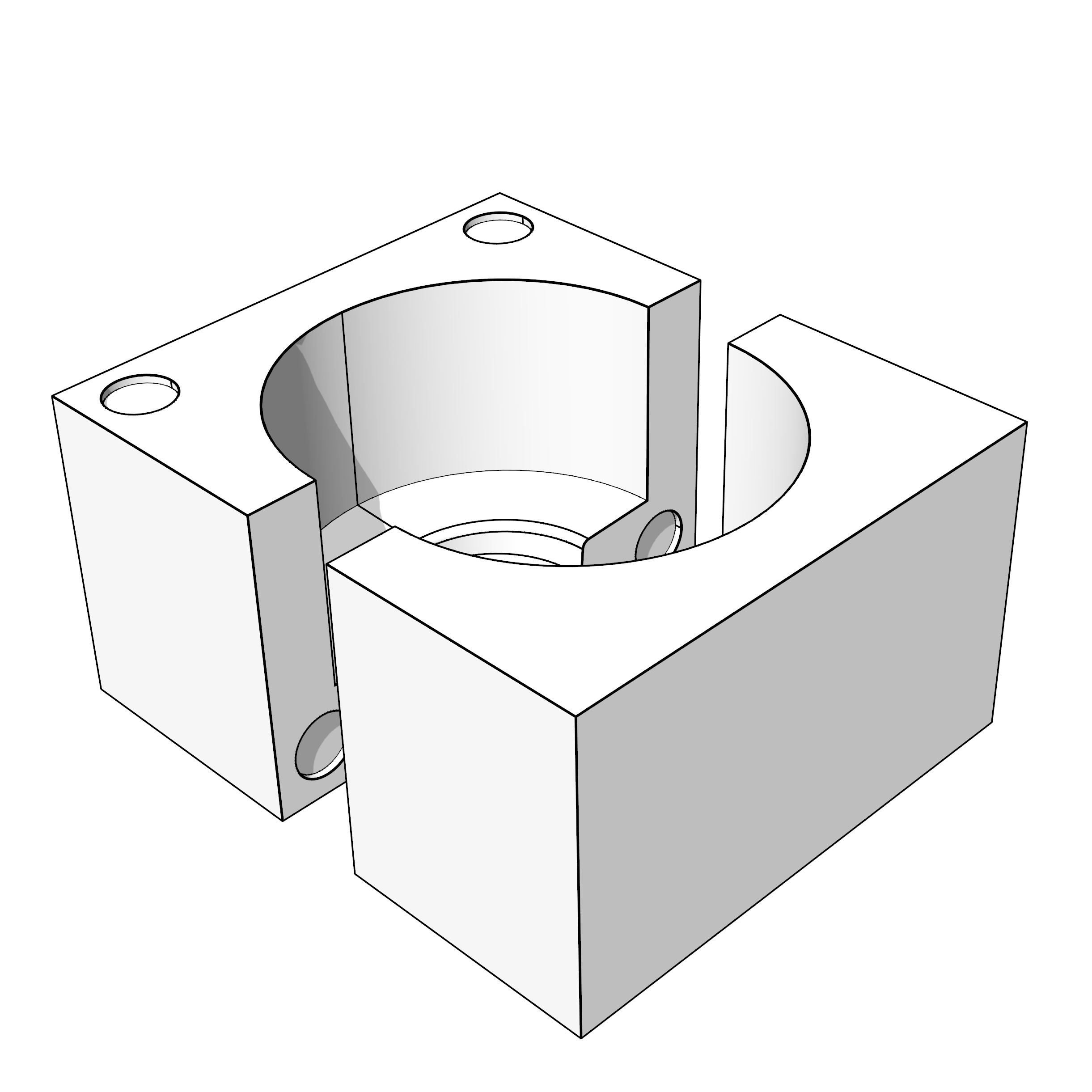

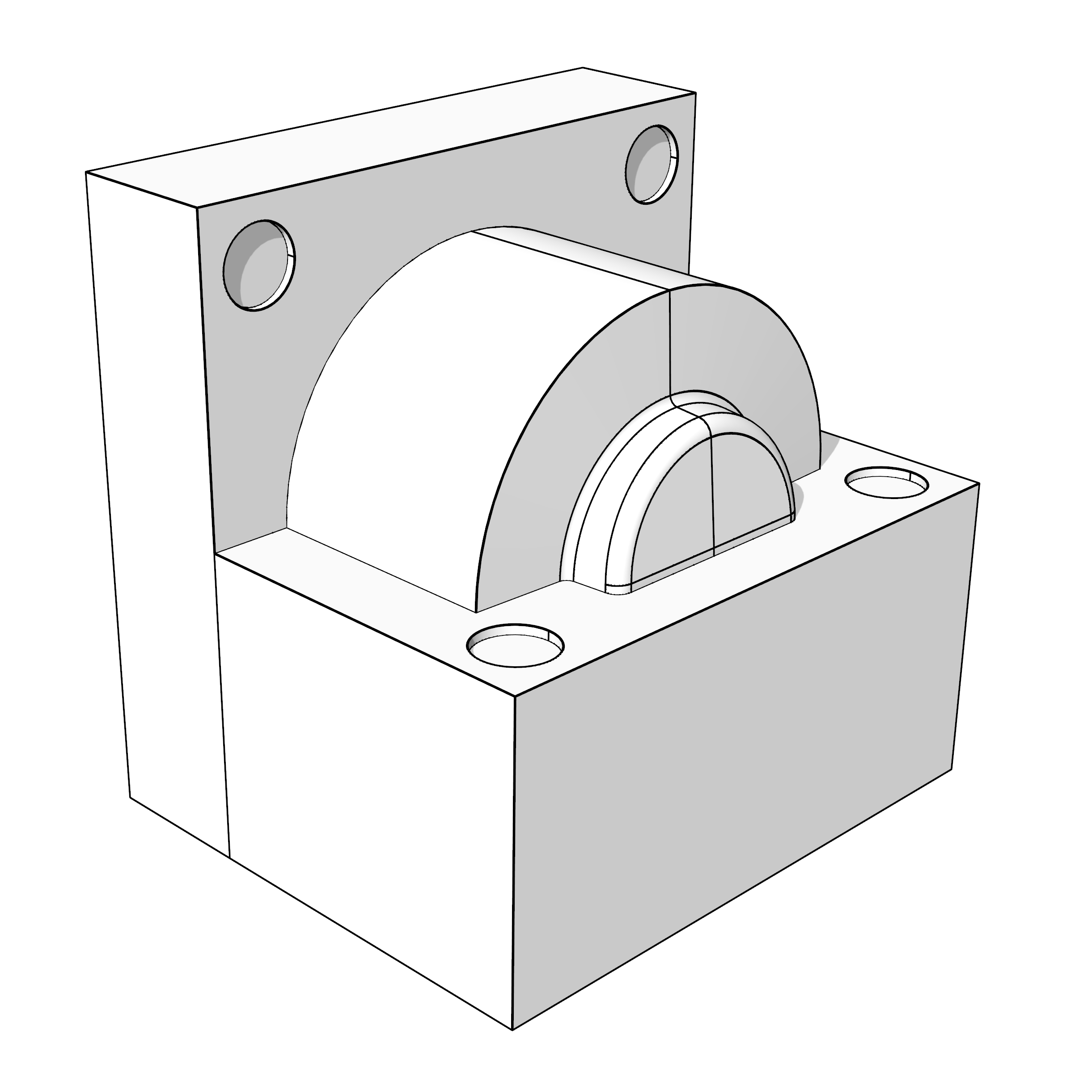

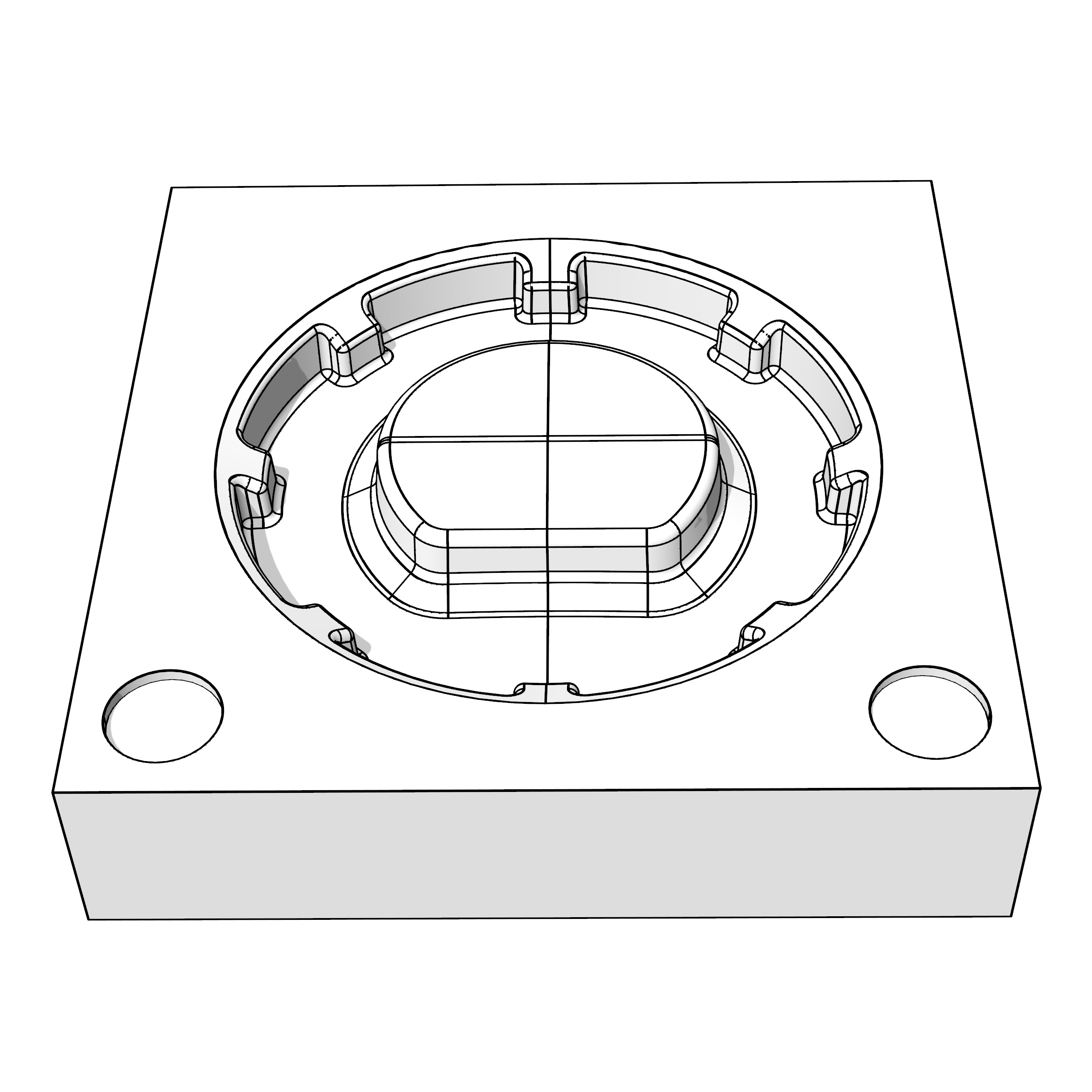

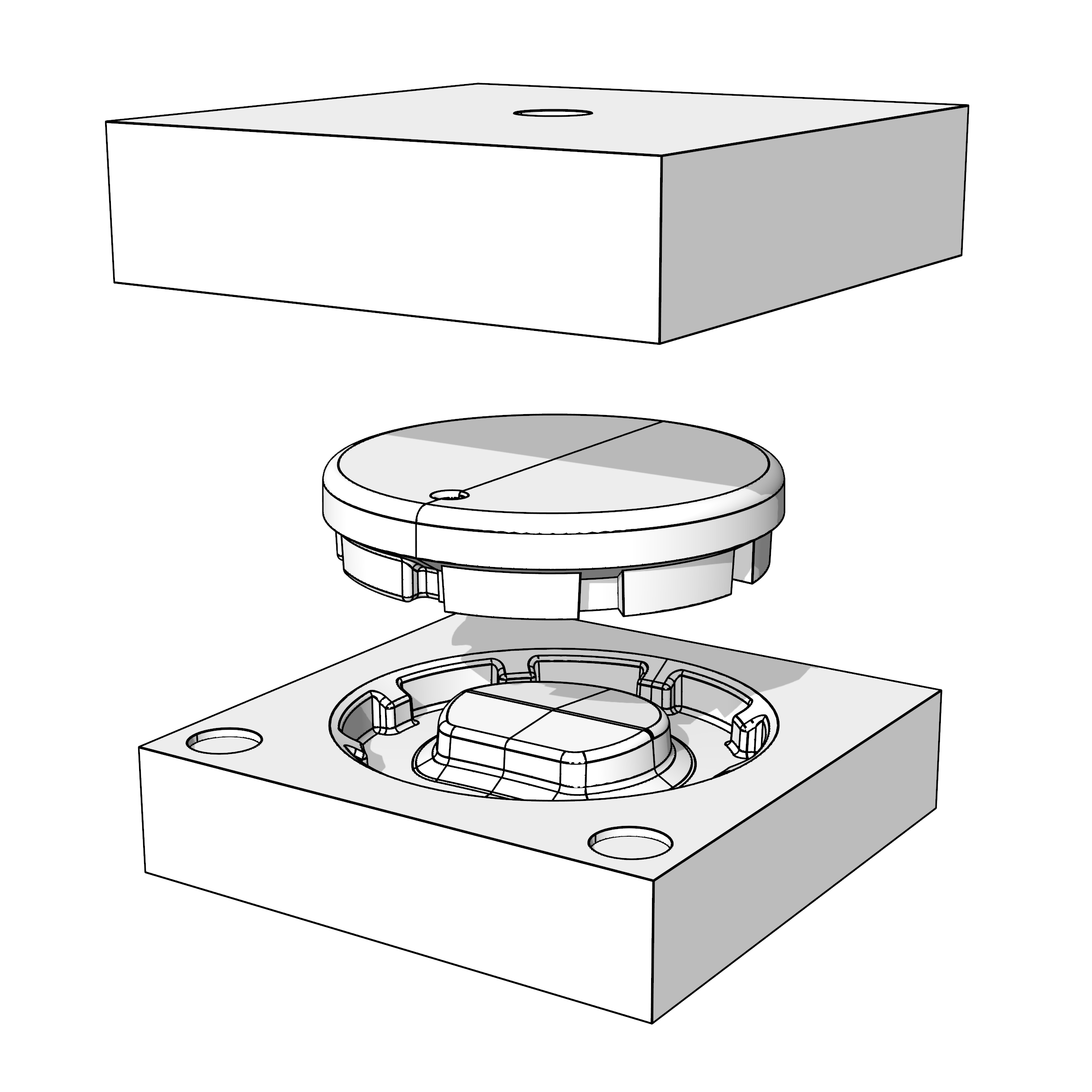

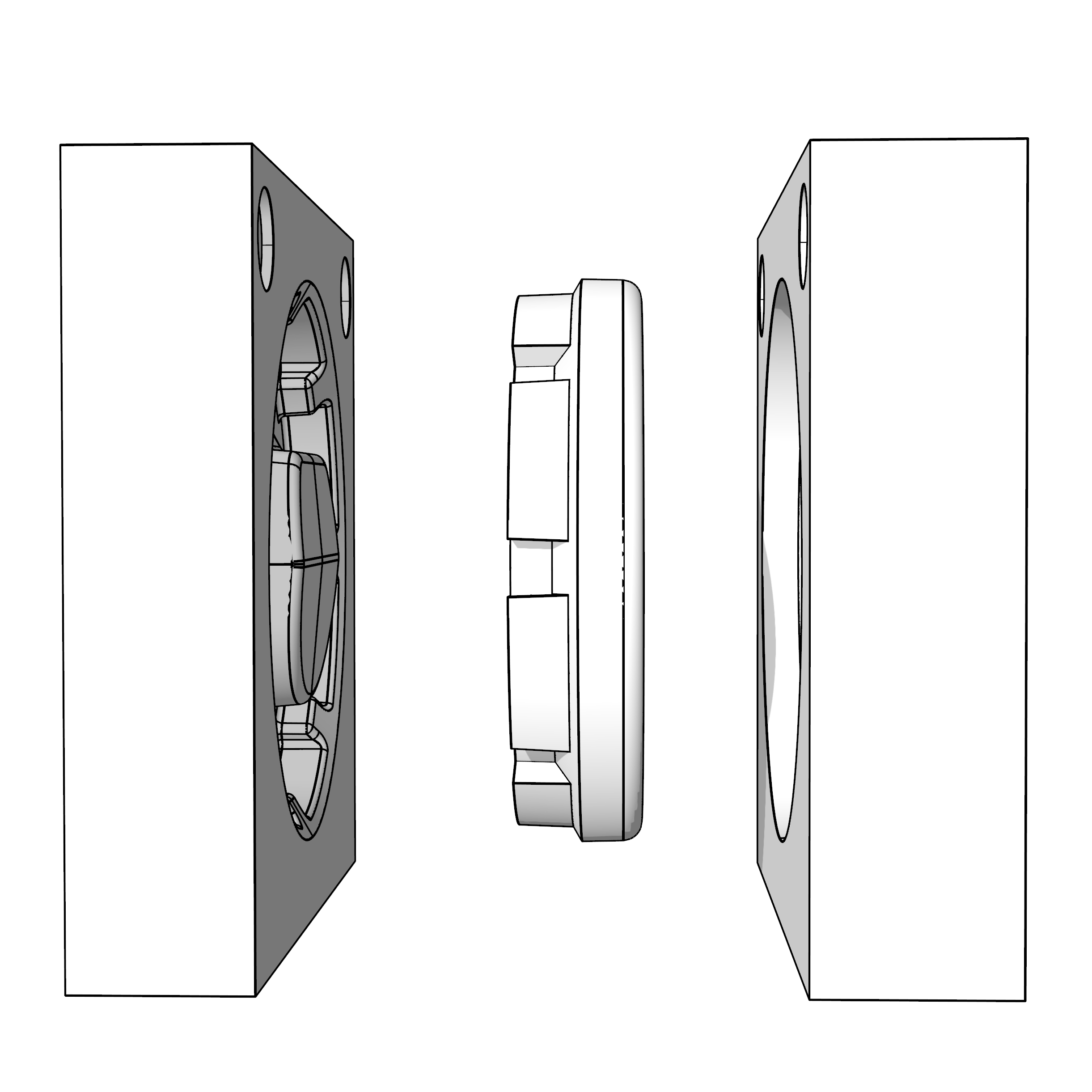

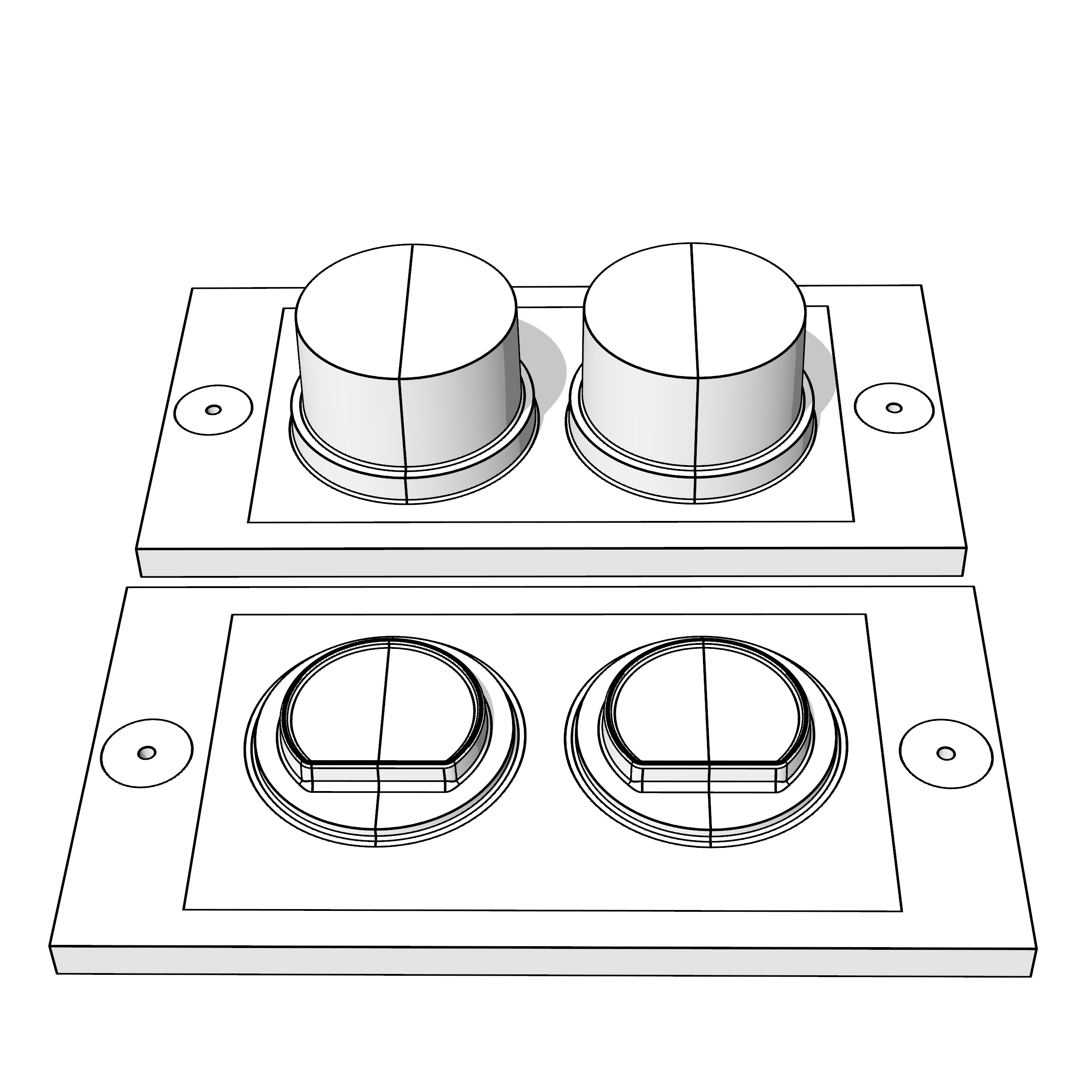

The model setup is developed on the basis of these adjustments. In this example, the set-up includes two core boxes and a double model, which is built on lower and upper box plates. This precise preparation is crucial in order to guarantee high-quality production and enable smooth implementation in the casting process.

Through careful planning and attention to all the necessary details, I ensure that the end product meets the highest standards and that functionality in use is always guaranteed.

Technical model making Sand casting:

- Raw part data + finished part data

- Construction of the model equipment, model plates OK/UK + core boxes