003 Fixture construction

The design of devices for placing, connecting, positioning, gripping components, etc. is an essential part of the modern manufacturing process. For rapid testing facilities, 3D printing offers an excellent way to create prototypes in a short time and with high flexibility. Additive manufacturing makes it possible to realize complex geometric shapes and works ideally for iterative test phases in which adjustments need to be made frequently and promptly.

CNC machining is the right choice for applications that require greater precision. This manufacturing process ensures precise machining and superior surface quality. Machining techniques are particularly advantageous when it comes to the production of components that have to work under extreme conditions or have special tolerances.

The choice between 3D printing and machining therefore depends heavily on the specific requirements of the project. While 3D printing offers a fast and flexible solution for prototypes, machining can be used to create durable and precise components that meet the high demands of series production. Therefore, it is crucial to select the appropriate method for designing the fixtures to ensure both efficiency and quality in a project.

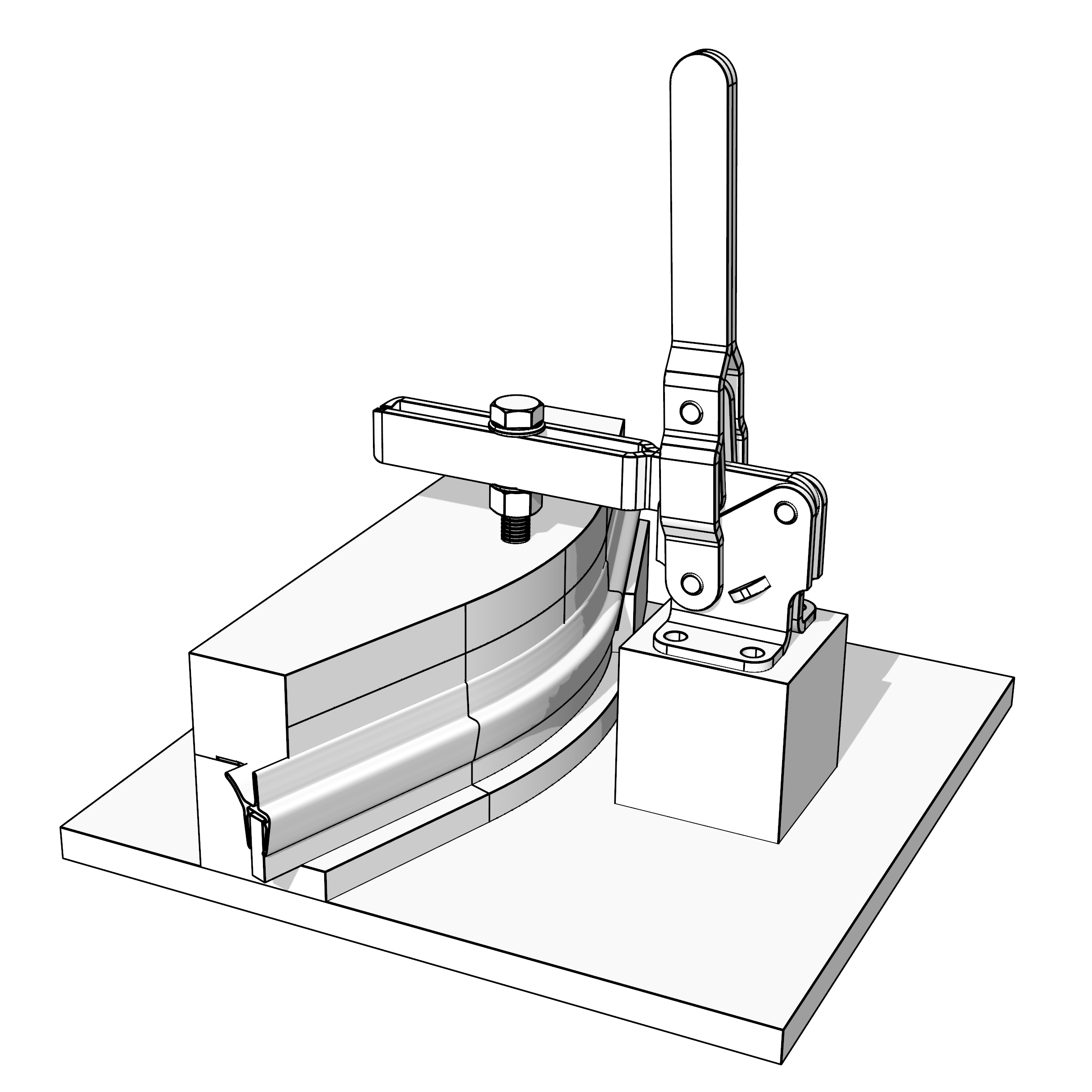

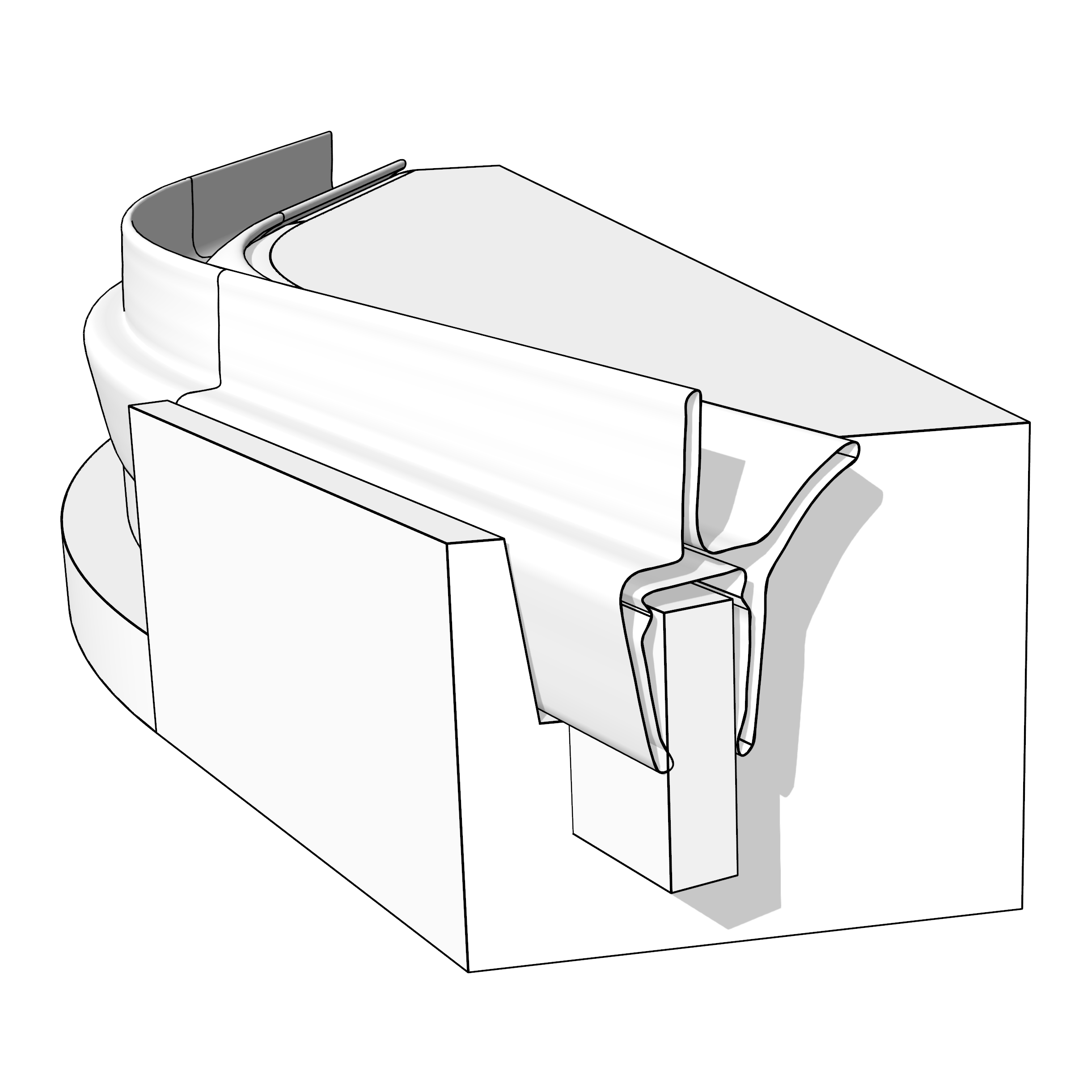

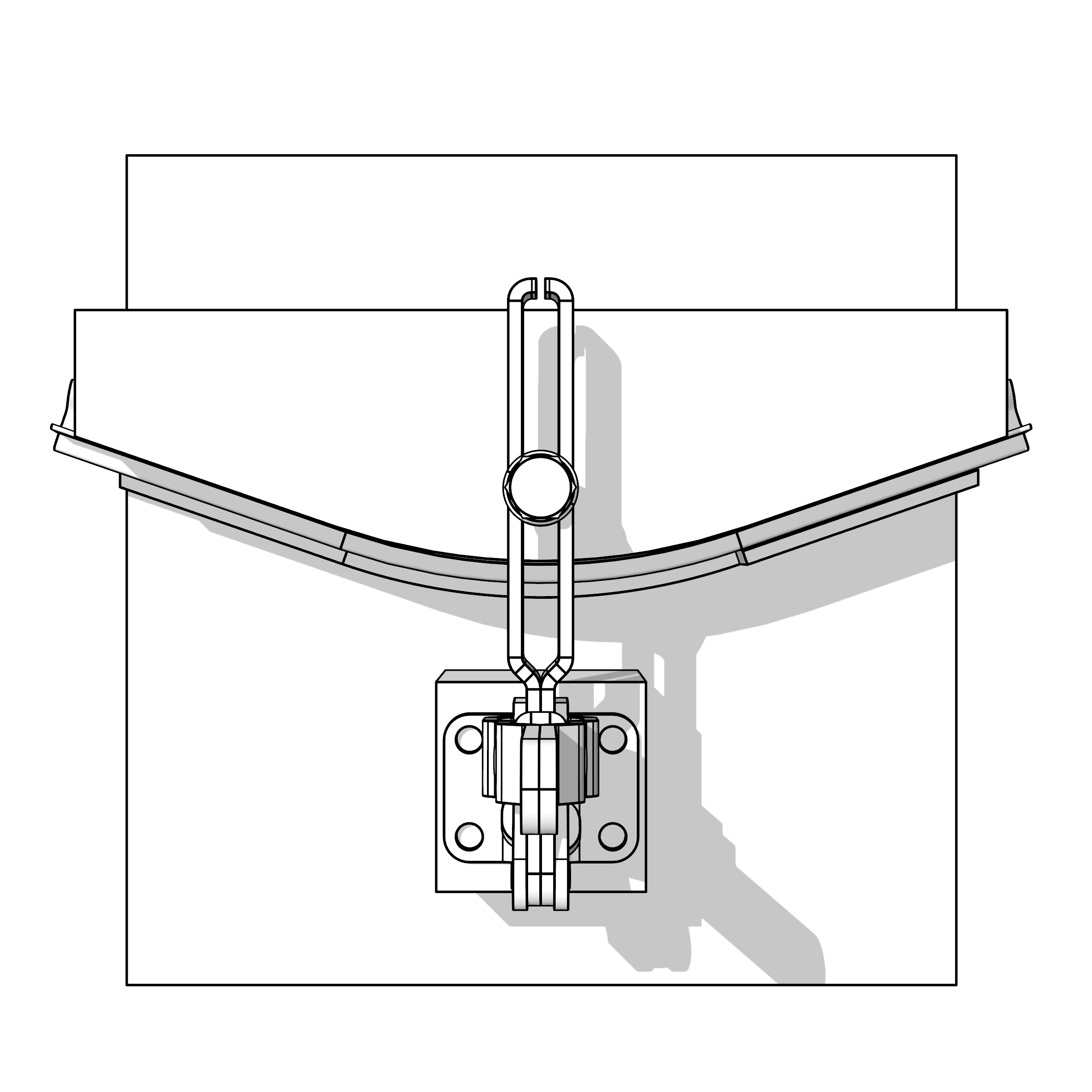

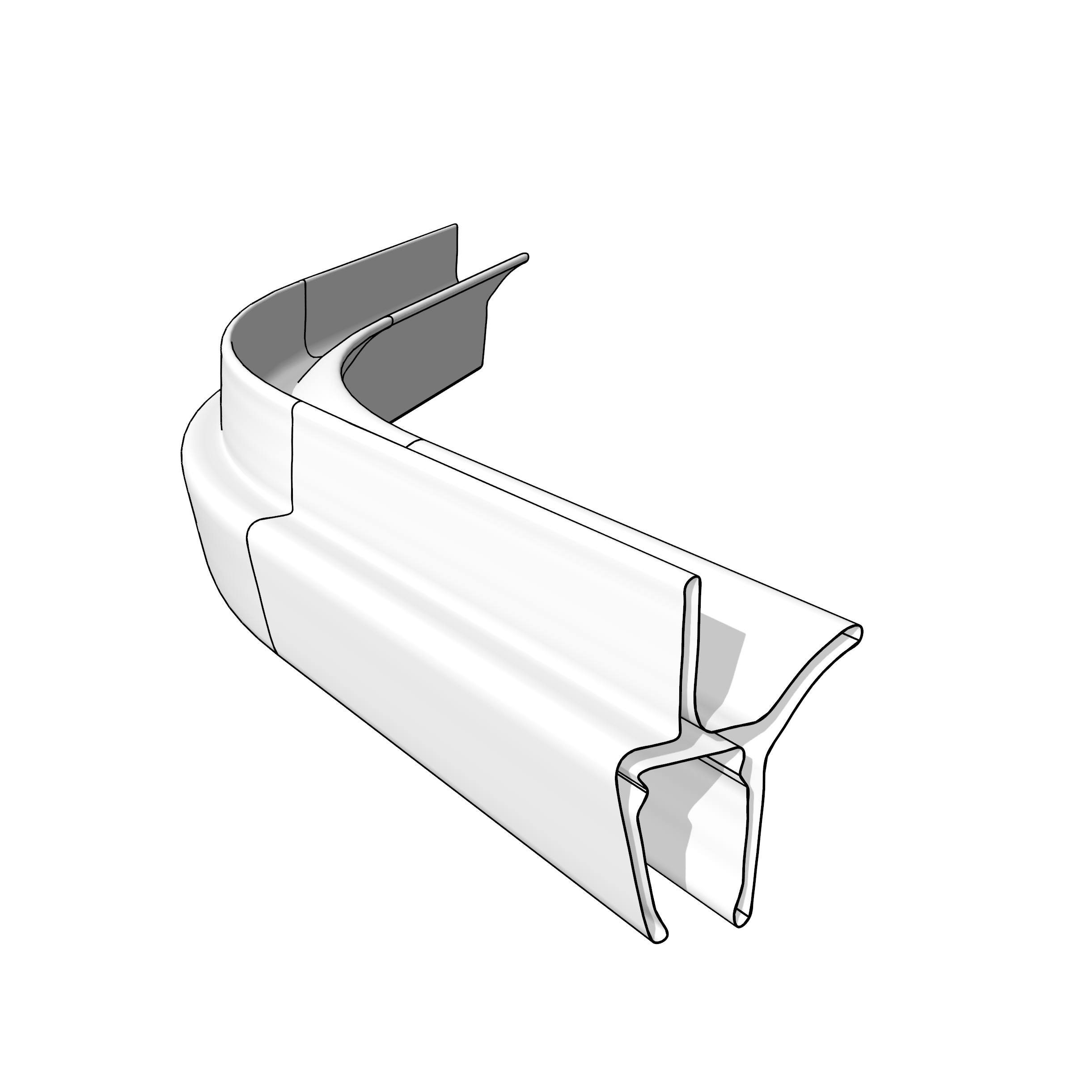

- Construction of devices and fixtures