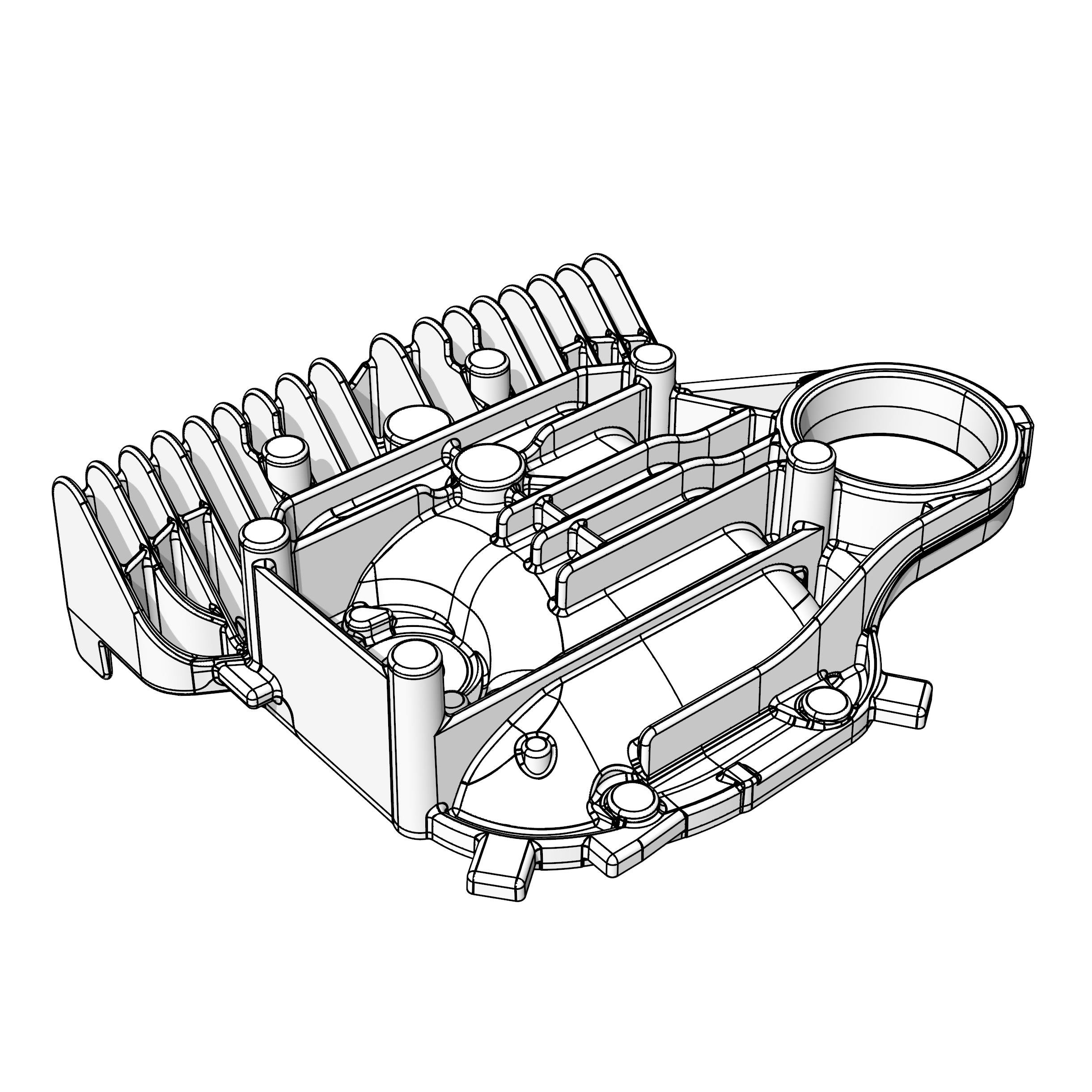

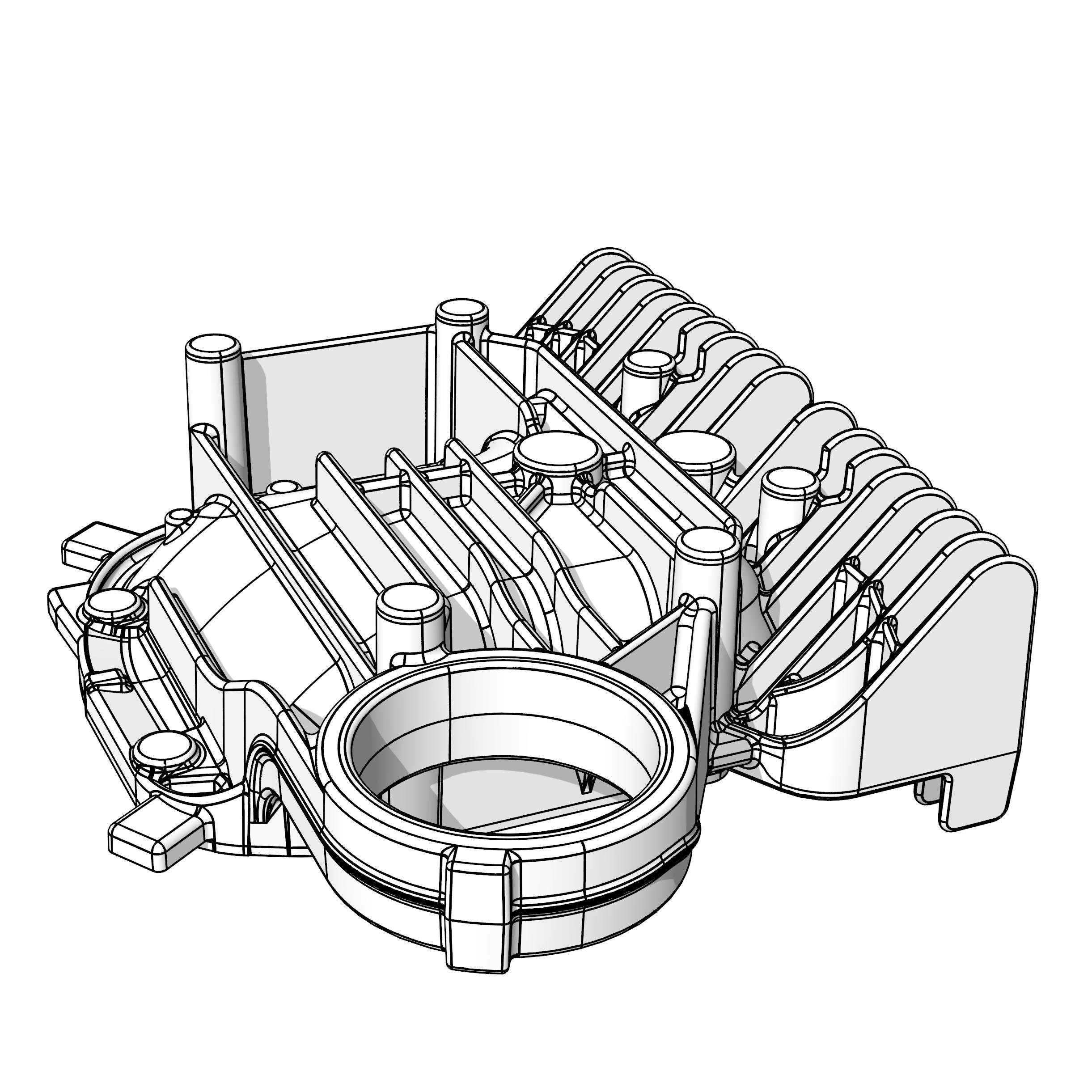

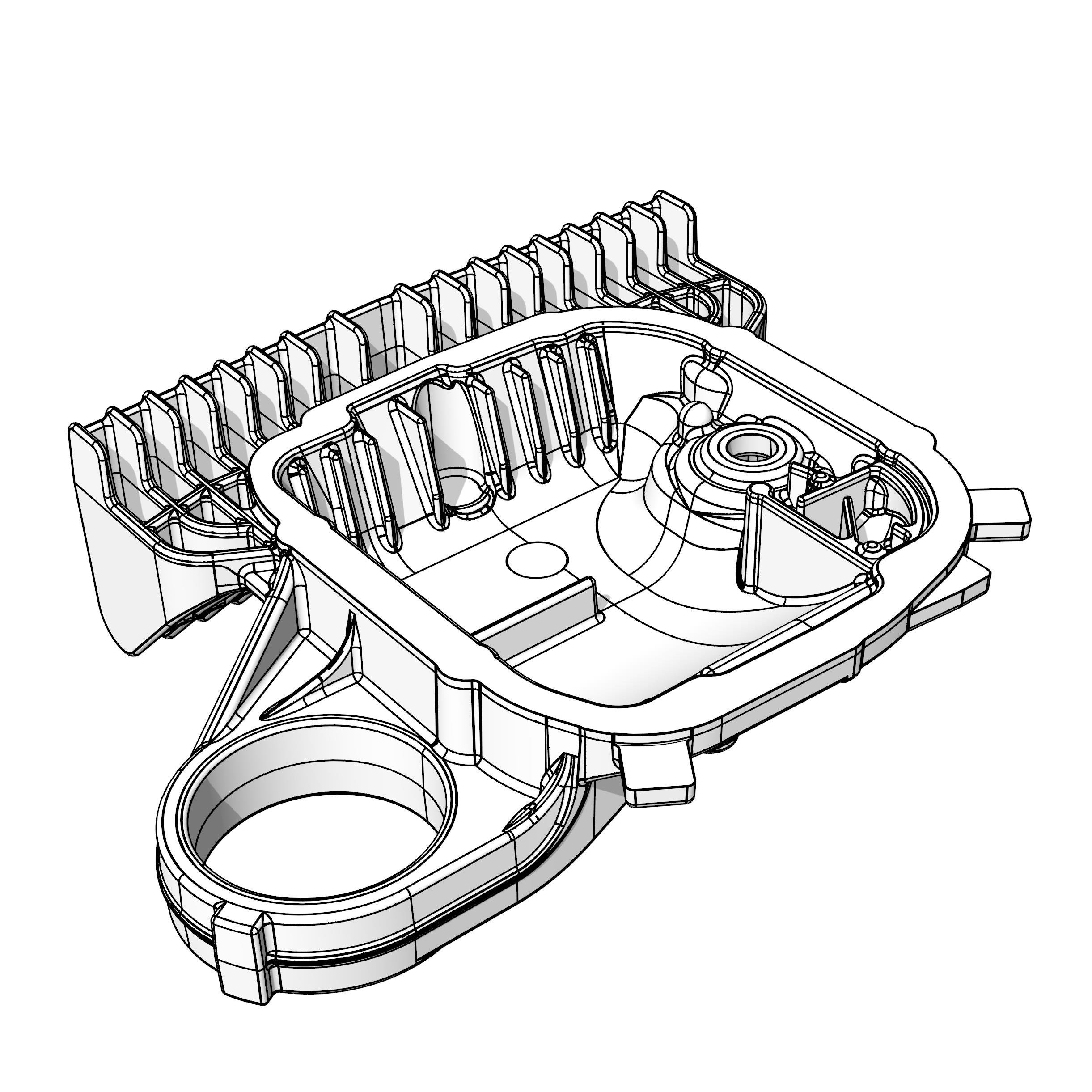

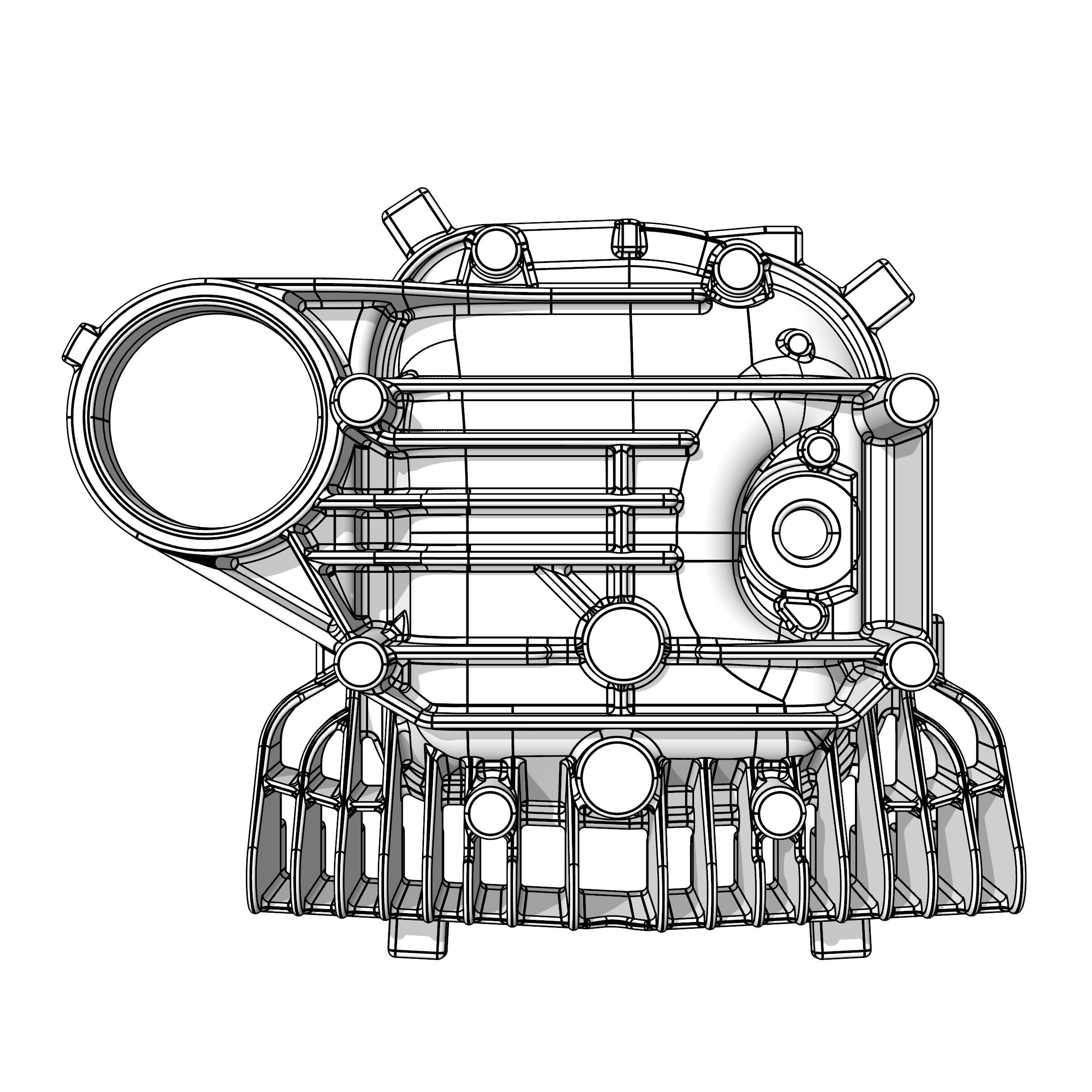

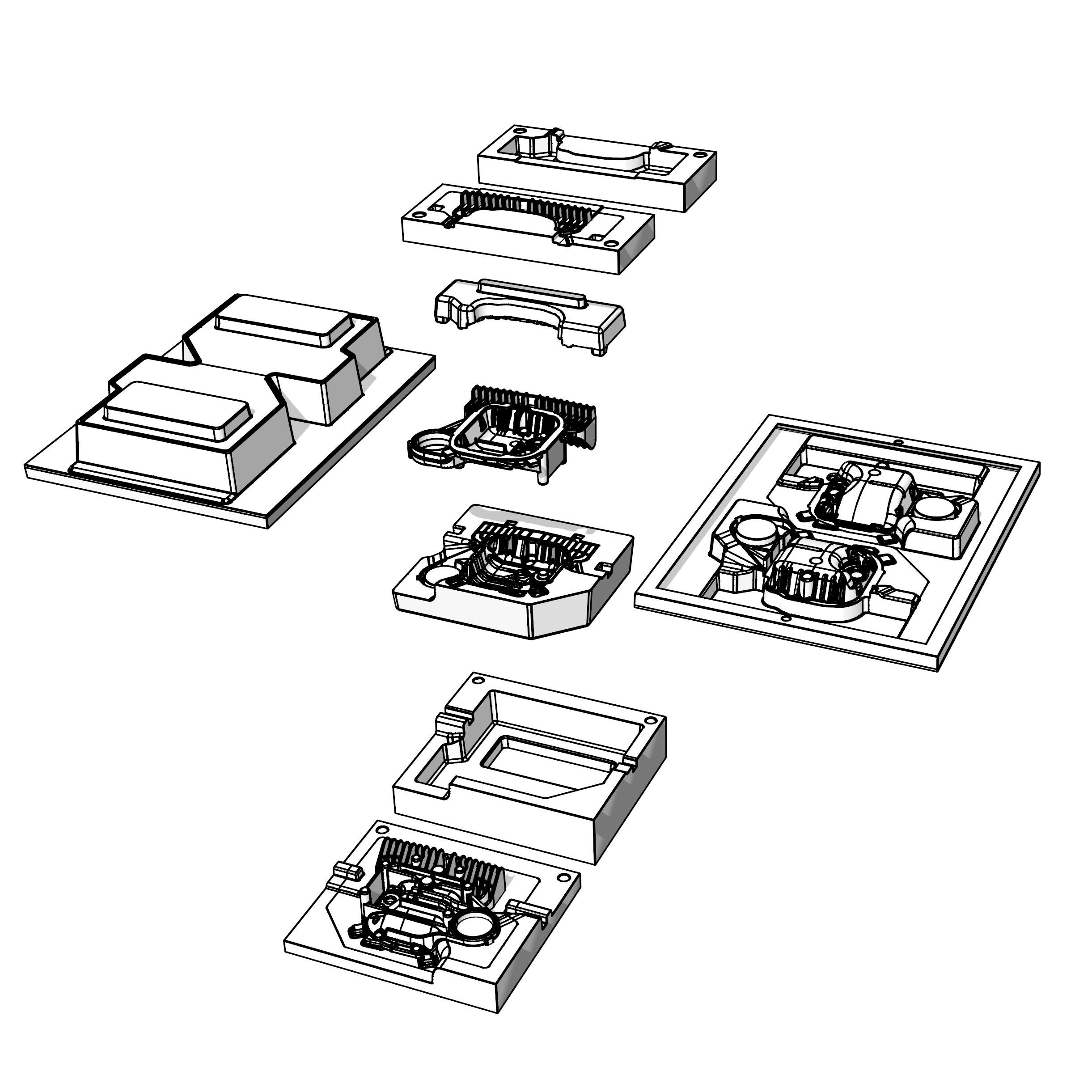

001 Gearbox cover

In this project, I accompany the entire process of manufacturing a casting, starting with the 2D sketch through to the finished product.

First, the 3D model is created from the existing 2D drawings. All relevant dimensions and details are taken into account to ensure a precise digital image of the cast part.

In the second step, I generate the data sets for the raw part and the finished part. This data plays a crucial role in further processing and serves as the basis for production planning.

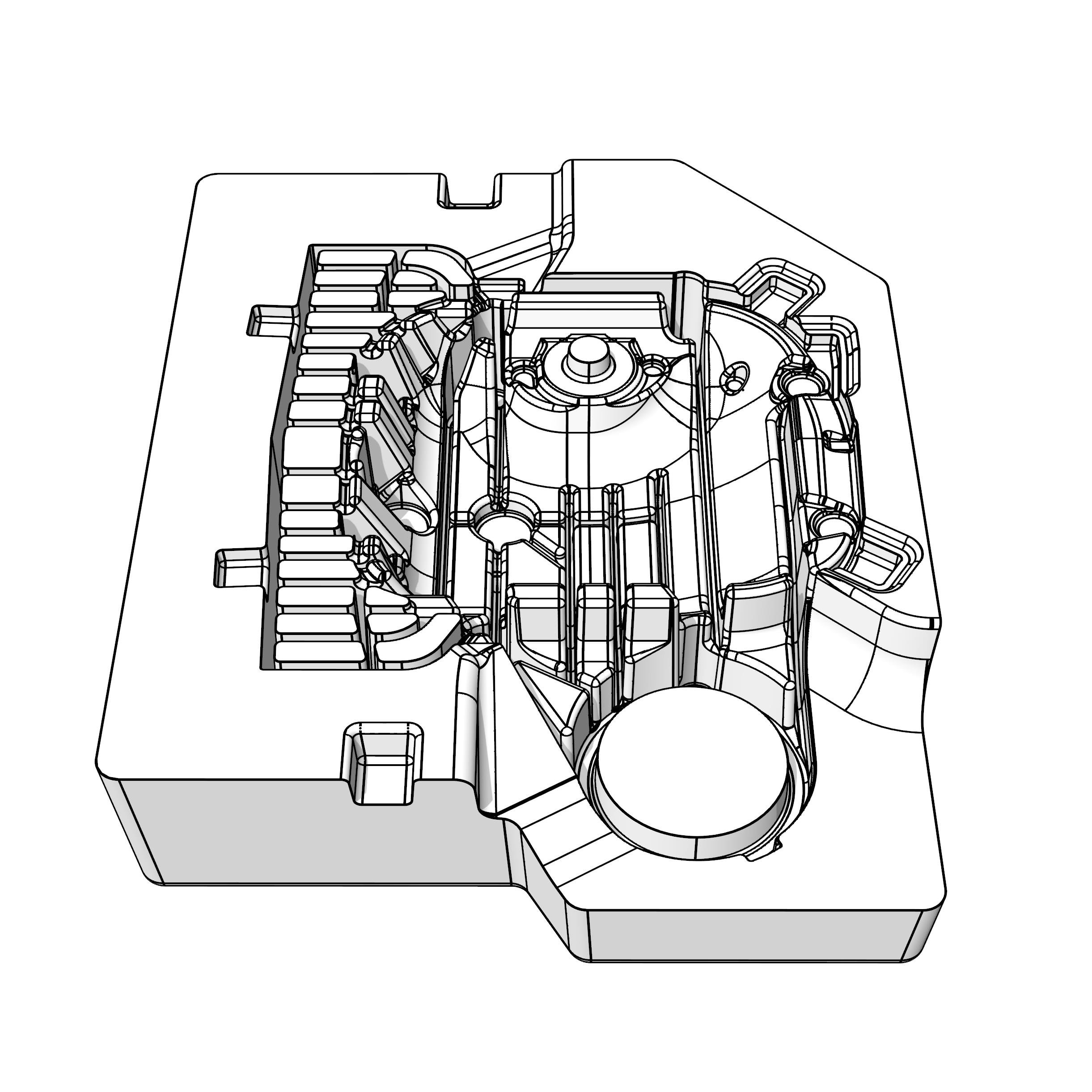

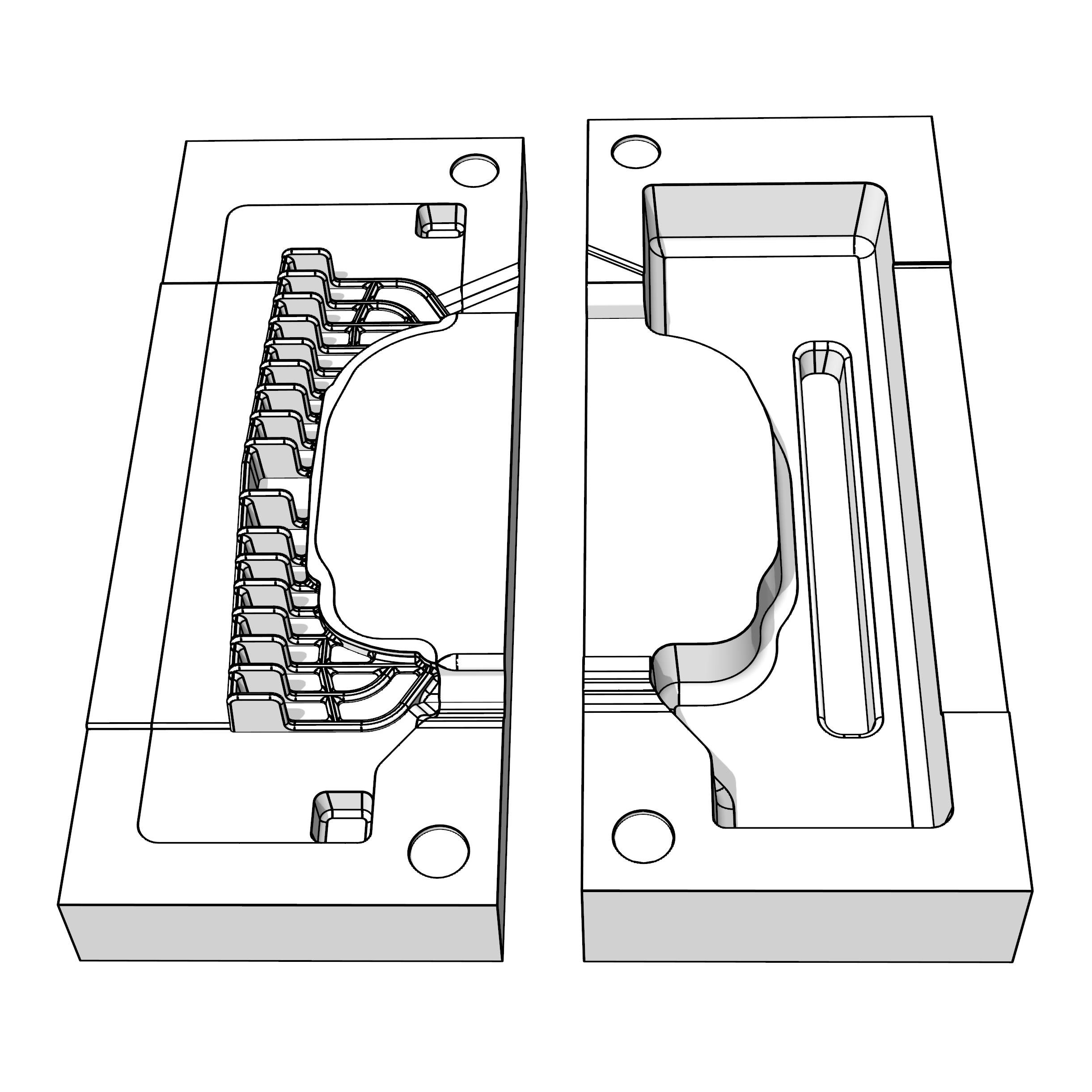

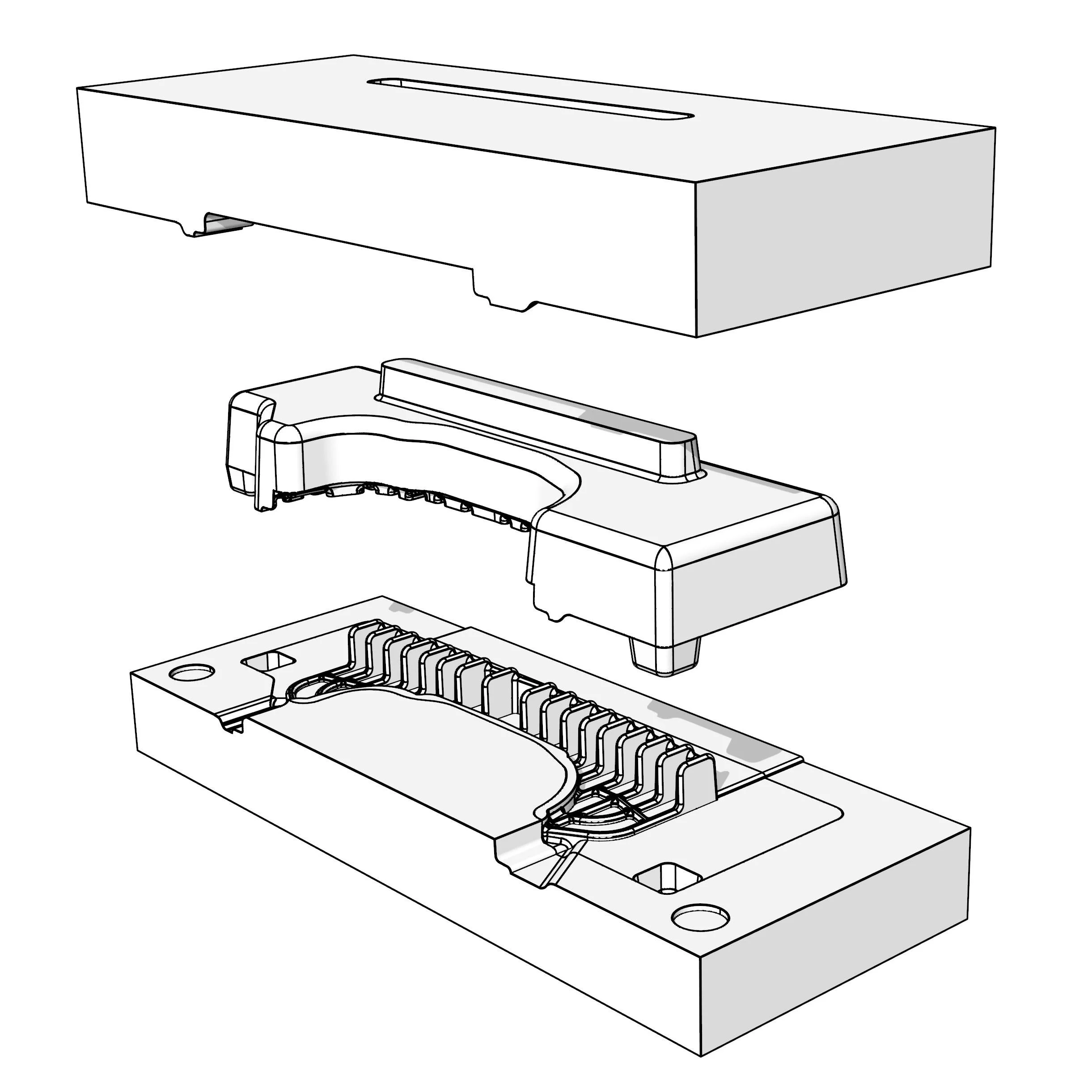

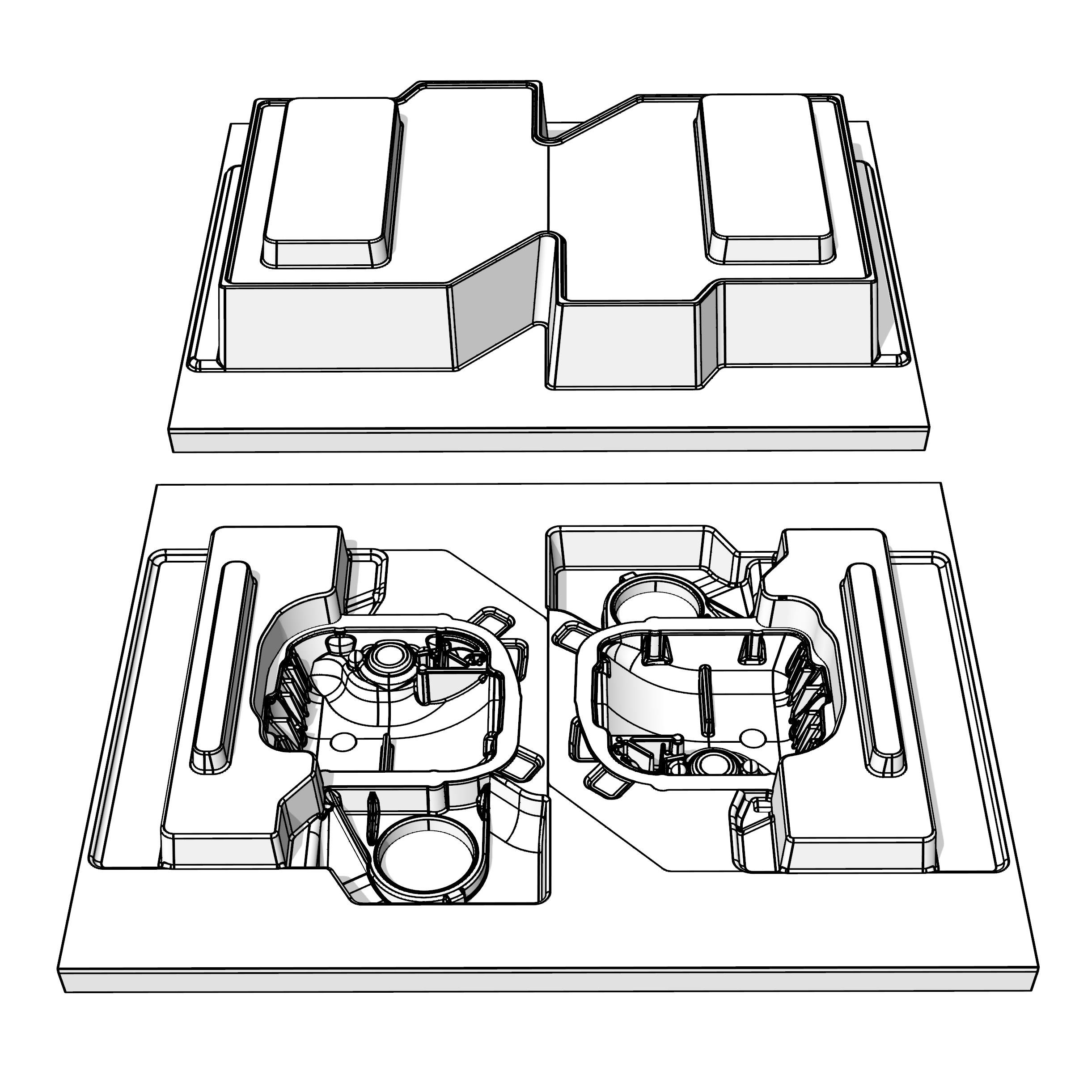

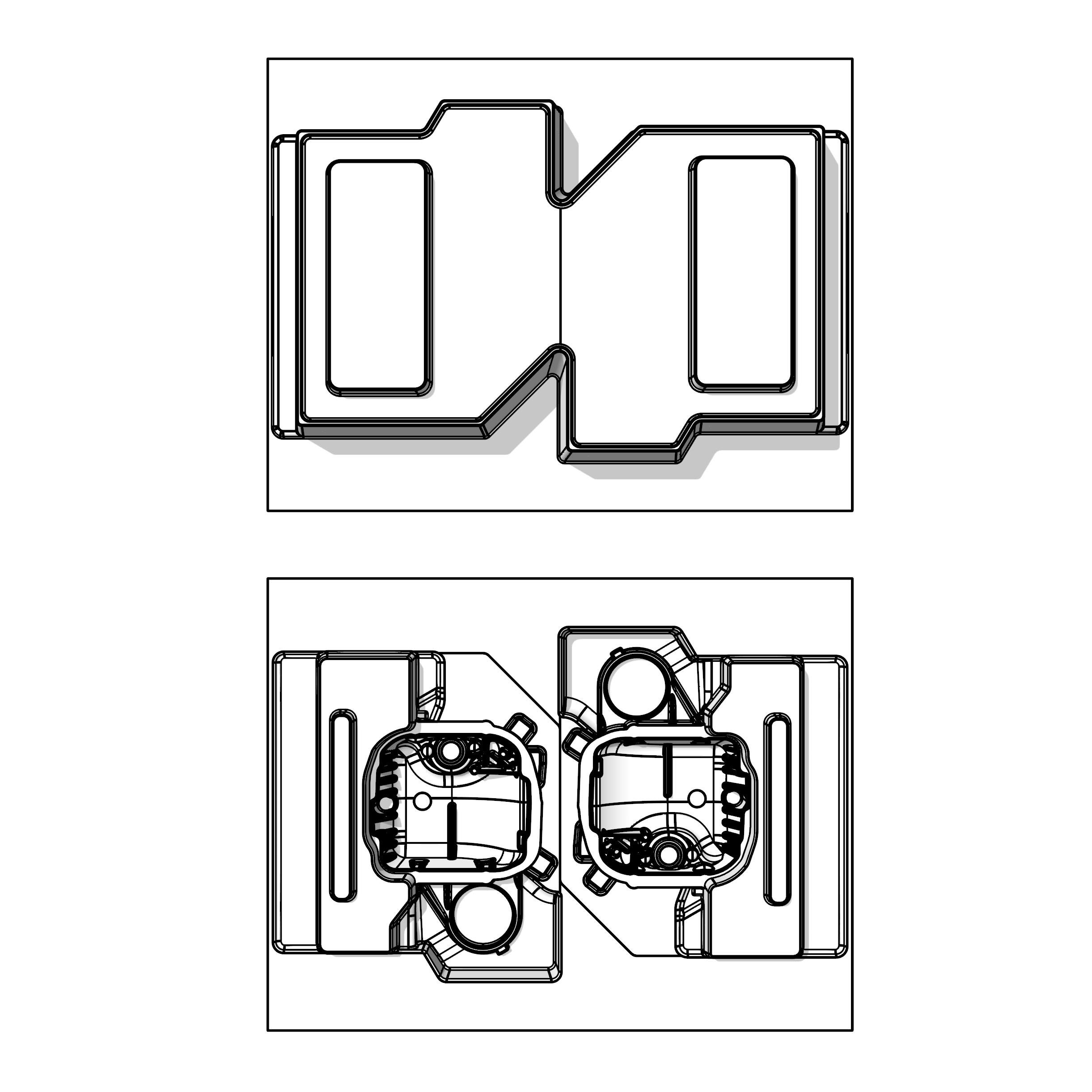

The foundry pattern equipment is then designed. This includes the production of the pattern plates and core boxes, which are essential for shaping the casting.

Each step is carried out with the utmost care to ensure that the final casting meets the highest quality requirements. The result is a precisely manufactured casting that meets all functional and design requirements.

Technical model making Sand casting:

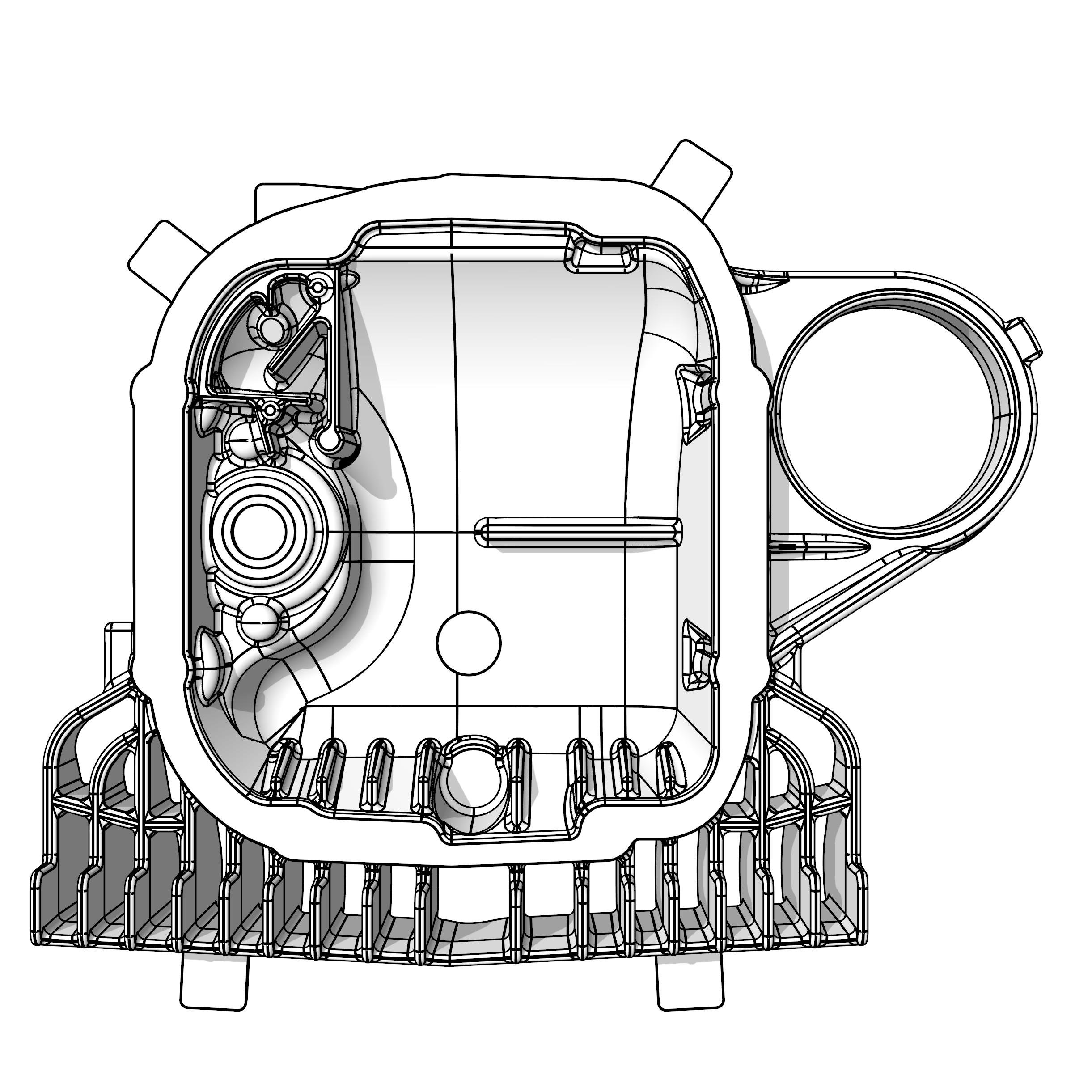

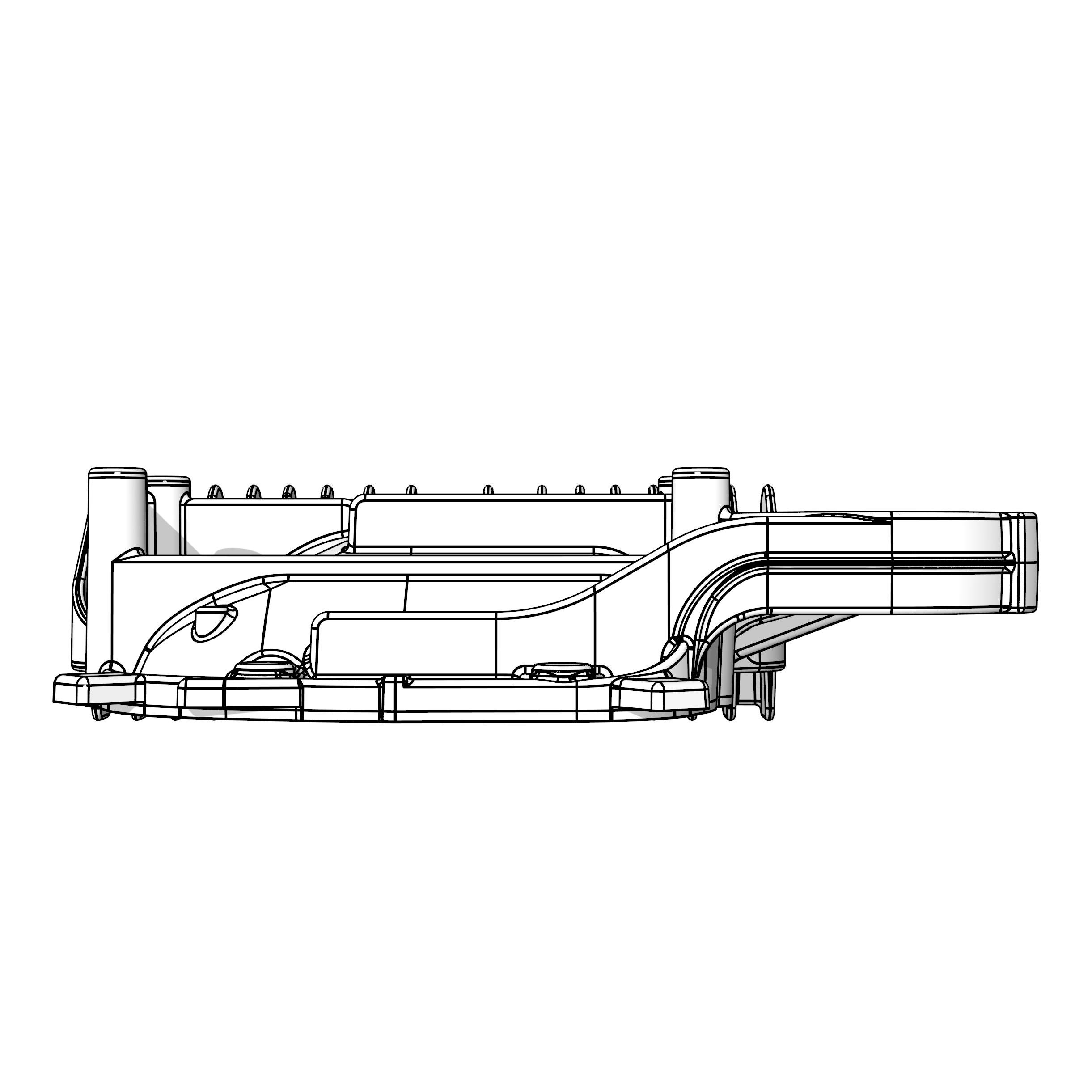

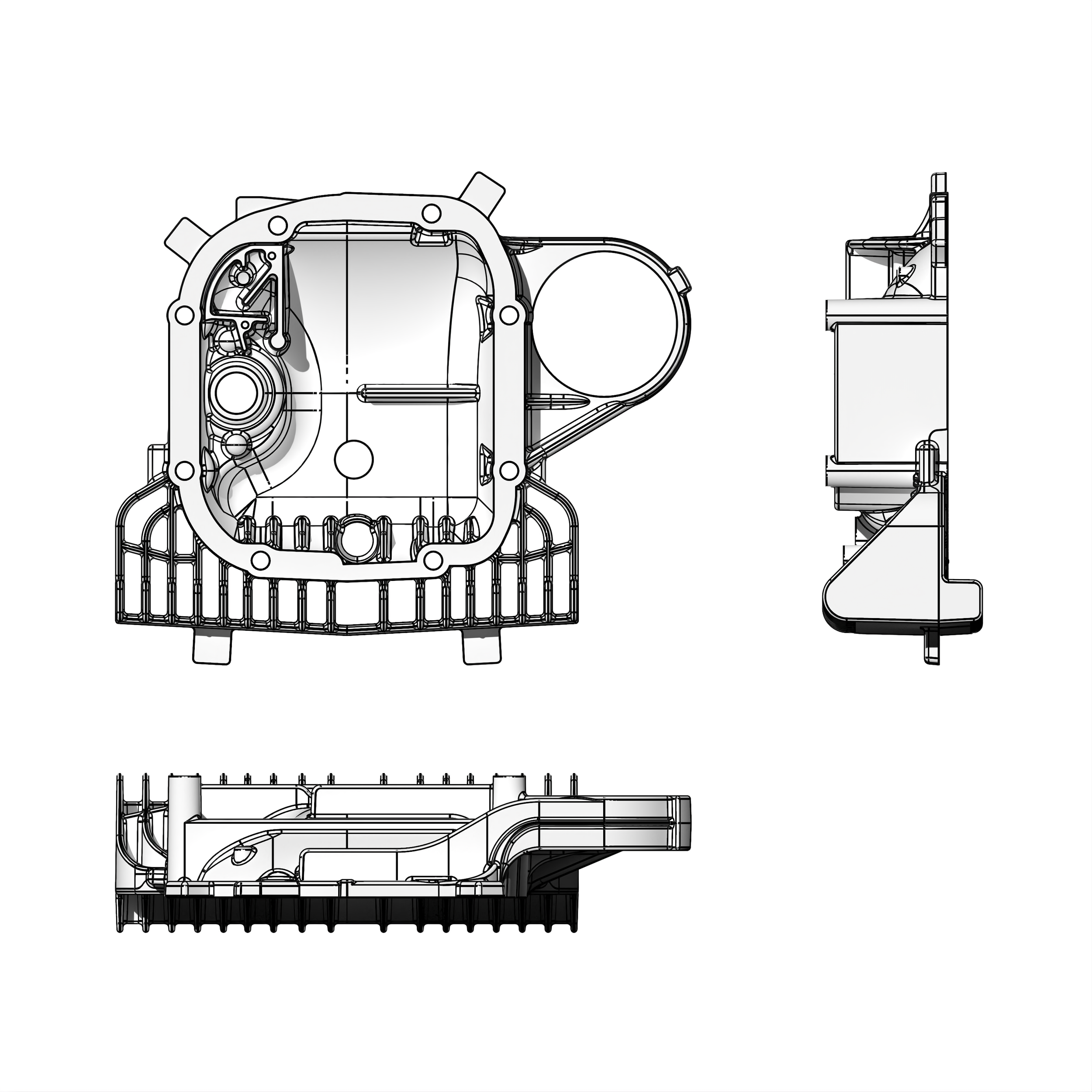

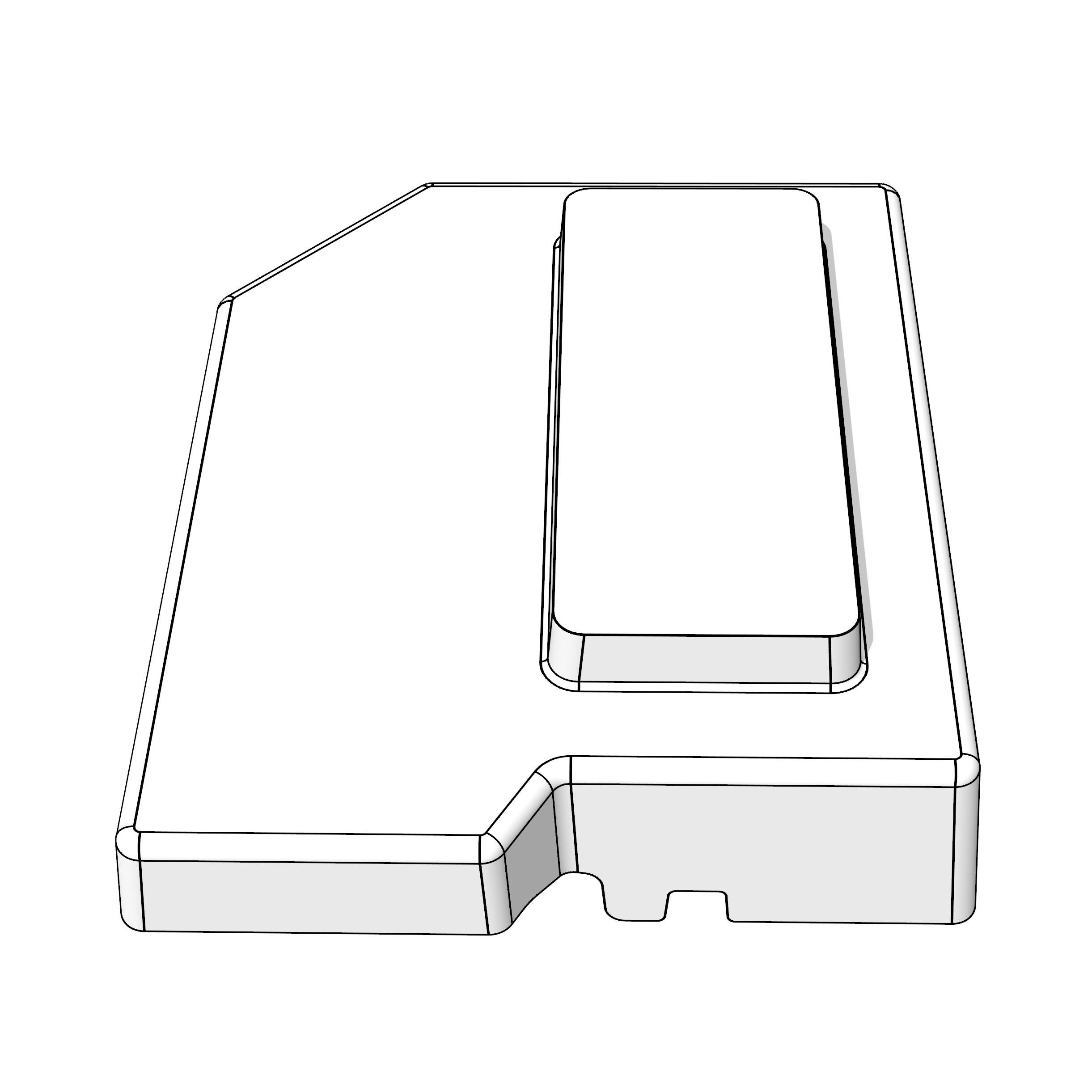

- 3D surface model derived from 2D drawings

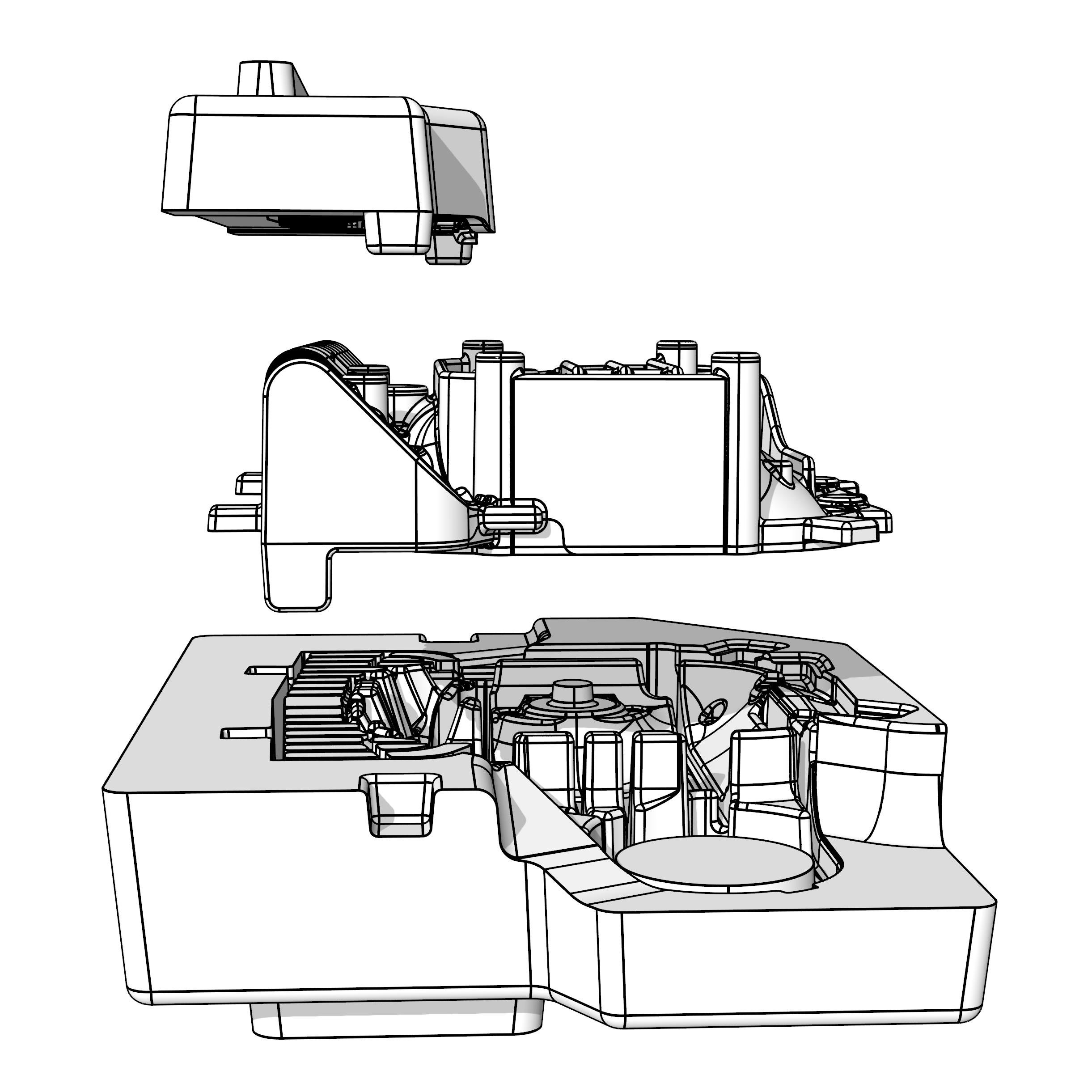

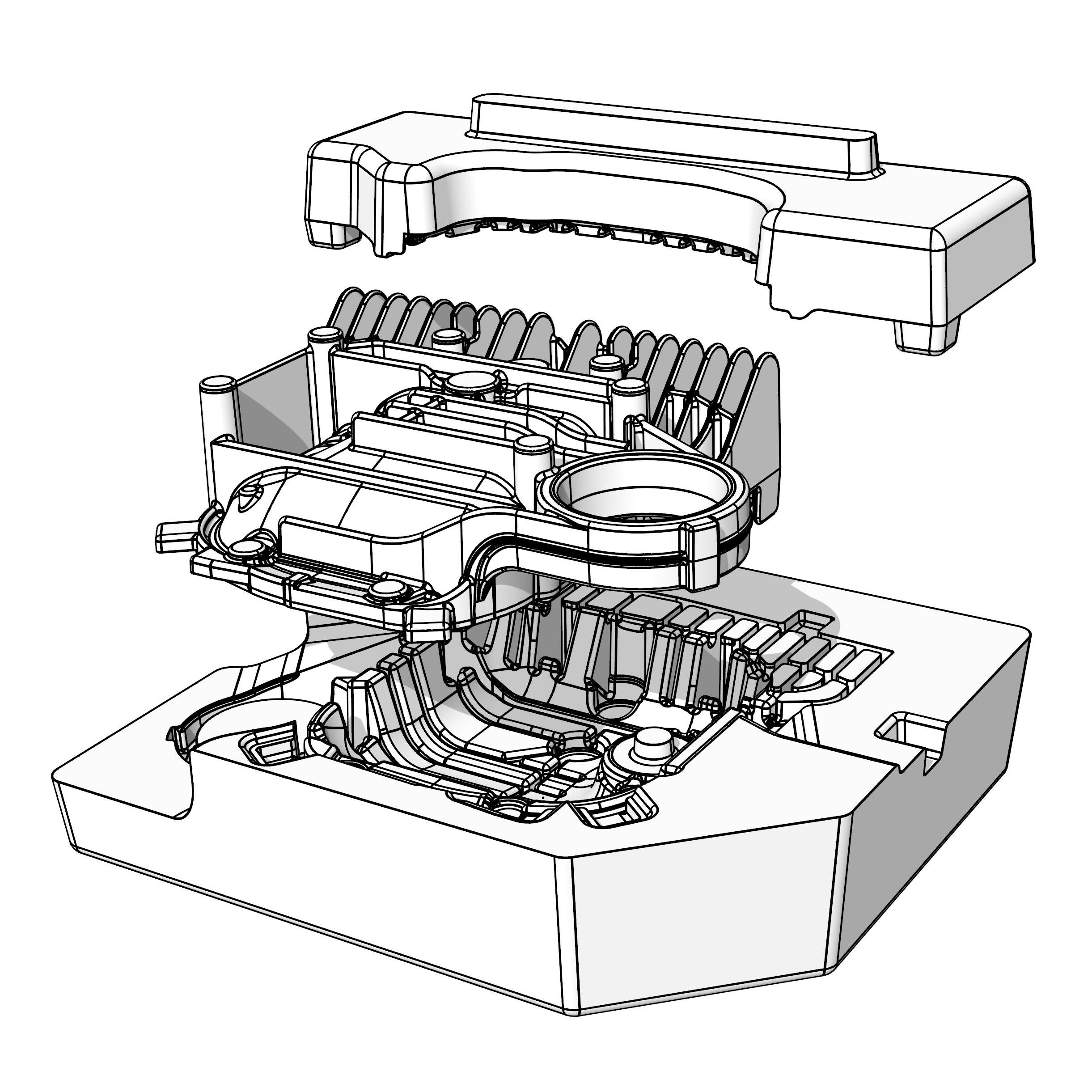

- Raw part data + finished part data

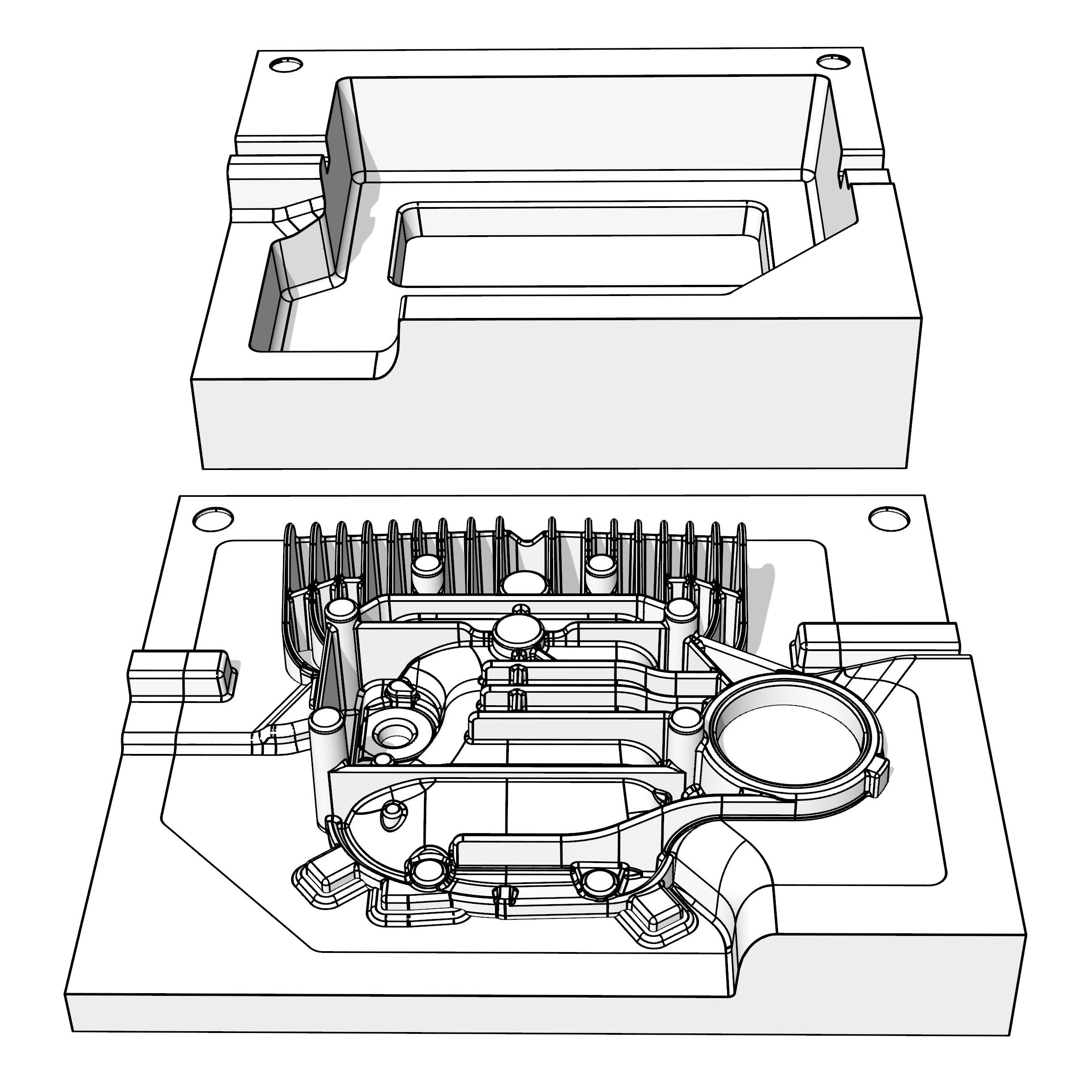

- Construction of the model equipment, model plates OK/UK + core boxes